|

|

BMe Research Grant |

|

Géza Pattantyús-Ábrahám Doctoral School of Mechanical Engineering

BME Faculty of Mechanical Engineering, Department of Polymer Engineering

Supervisor: Prof. Dr. h.c. Karger-Kocsis József

Preparation and Characterization of Thermoplastic-Based Micro- and Nanocomposites by Using Suspension-Assisted Compounding

Introducing the research area

Thermoplastic polymer micro- and nanocomposites received considerable scientific and technological interest in the last decades, especially in the field of vehicle industry. These types of structural materials are relatively new, thus there is no conventional way for their preparation yet. In my research I use a new method called water-assisted compounding to prepare micro- and nanocomposites.

Brief introduction of the research place

I am doing my PhD research project in the accredited research facility of the Department of Polymer Engineering at the Budapest University of Technology and Economics. The advanced laboratory equipment as well as the ISO 9001 quality and ISO 14001 environmental management systems enables the execution of the R&D projects at high standards. The high level scientific activity is marked by the department’s own international journal, Express Polymer Letters.

History and context of the research

The spreading of modern polymer composites is strongly related to the development of glass fiber as reinforcement. After its appearance, fiber-reinforced structures became the focus of attention in materials development. Micro- and nanoparticles only appeared in the early 90’s and became new, essential reinforcing fillers especially in the vehicle industry (Fig. 1) [1-3].

Figure 1: Nanocomposites used in car industry [4]

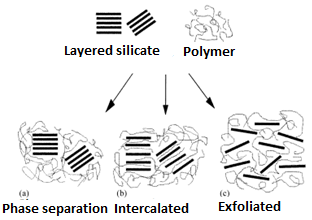

The properties of the polymer matrix can be greatly enhanced at a relatively low amount of filler loading compared to conventional fiber-reinforced composites, due to the higher specific surface area of micro- and nanoparticles. The main problem is that these particles have a high tendency to form bundles, called agglomerates [5]. Therefore it was a significant challenge for engineers and scientists in the last two decades to separate those initial agglomerates into individual particles (Fig. 2.). These days there are three traditional methods to prepare nanocomposites: in situ polymerization, melt mixing and solvent-assisted techniques. Each has its advantages and disadvantages, thus there is no commonly used method. In my work I conduct research into a relatively new method: the water-assisted technique [L1].

Figure 2: The level of separation of agglomerates [5]

Another problem is that thermoplastic micro- and nanocomposites containing different reinforcing particles have outstanding mechanical performance, except toughness. A good solution can be to introduce toughening fillers (rubbers) as well, preferably along with the reinforcement, with the use of an aqueous suspension.

The research goal, open questions

The aim of my study is to prepare thermoplastic-based micro- and nanocomposites by water-assisted melt compounding, where the stiffness, strength and toughness of the matrix are simultaneously enhanced. If that works out well, then both the reinforcement and the toughener are to be introduced in an aqueous suspension, possibly in one step. The presence of the water-based liquid media should improve the dispersion of nanoscale particles. In most cases water is to be removed, as it would only cause the hydrothermal decomposition of the matrix. This manifests itself in products of substantially lower molecular weight, which should be counterbalanced. There are, however, some exceptions, like thermoplastic starch, where water is an indispensable plasticizer, which should not be removed totally during compounding. In this case gelatinization of starch and dispersion of nanosized reinforcements can be performed simultaneously [6]. In my work I develop composites of not only petrol-based polymers, but also biopolymers, made from agricultural plants grown worldwide. Moreover, I aim to compare the efficiency of additives from renewable resources with those of synthetic origins, thereby supporting sustainability.

Methods

The methods used in my research can be divided into two categories. At first I worked on the techniques to produce micro- and nanocomposites. Subsequently, I tested the samples to explore the changes in properties.

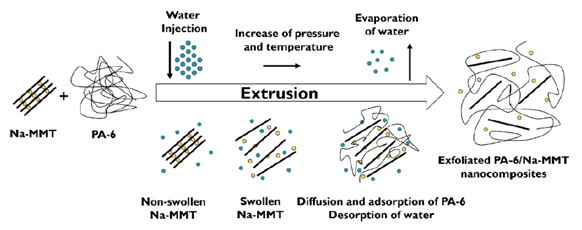

I prepared composites using two forms of traditional thermoplastic techniques: continuous and batch type compounding. Continuous compounding was done with a twin-screw extruder, also widely used in the polymer industry. Batch type mixing was carried out in an internal mixer. In both cases the additives were introduced in an aqueous media (Fig. 3). The prepared composites were then compression molded to sheets in a hot press machine. Specimens for different tests were punched from the compression molded sheets. In some cases I used injection molding, a widely used thermoplastic technology. I also dried or conditioned the raw materials and the prepared samples when it was necessary to obtain reproducible results.

Figure 3: Schematic diagram of montmorillonite (MMT) exfoliation in polyamide 6 (PA-6) during water-assisted melt compounding [L1]

Following the preparation, I tested the composite samples using different techniques to analyze the changes in the structure and properties of the polymer caused by the additive. Mechanical, thermal, morphological properties were examined in the first place. Static mechanical properties (stiffness, strength, deformation) were determined by tensile tests. Dynamic mechanical properties were analyzed by Charpy impact tests. In some cases dynamic mechanical analysis (DMA) was also carried out in a justified temperature range to determine storage modulus, loss factor and glass transition temperature. Morphological analysis was performed by scanning electron microscopy (SEM) and atomic force microscopy (AFM). To examine changes in crystallinity, I performed differential scanning calorimetry on the samples. Thermal decomposition temperatures were determined by analyzing thermogravimetric analysis (TGA) traces. When it was necessary, I also performed X-ray diffraction (XRD) to measure the intergallery distance of nanoplatelets.

Results

Biodegradable polymer based nanocomposites

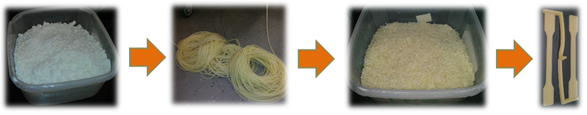

Throughout my work in the field of biodegradable polymer-based nanocomposites, I used thermoplastic starch (TPS) as base material. I prepared TPS on my own using native maize starch plasticized with glycerol and water (Fig. 4).

Figure 4: Preparation of thermoplastic starch specimens from native maize starch by extrusion, followed by injection molding

To support sustainability, I performed three different experiments based on TPS. In the first one, I examined the possibility of reinforcing TPS with microfibrillated cellulose [L2-L4]. I figured out that the presence of water highly facilitates the dispersion of micro-scaled cellulose particles in the matrix. Using cellulose of two sizes (both on the micro scale), I also showed that microfibrillated cellulose particles below critical fiber length influence the mechanical properties of thermoplastic starch the same way.

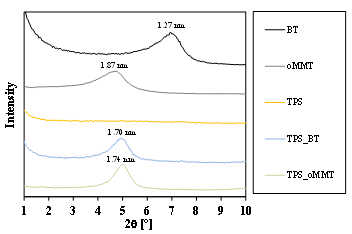

In my second experiment I produced layered silicate reinforced TPS to investigate the relationships between structure and properties in the presence of layered silicates with different characteristics [L5,L6]. The two types of layered silicates incorporated as reinforcements were organically modified montmorillonite and bentonite (designated further as oMMT and BT, respectively). While organo-montmorillonite has a larger intergallery distance than bentonite due to its modification, it is hydrophobic contrary to bentonite, which is highly hydrophilic. Using XRD measurements, I showed (Fig. 5) that the intergallery distance of bentonite platelets increased by 34% thanks to water-assisted production (1.27 nm => 1.7 nm). Meanwhile, this distance decreased for hydrophobic oMMT (1.87 nm => 1.74 nm).

Figure 5: XRD results for TPS and its nanocomposites containing bentonite

and organically modified montmorillonite

In my last experiment with TPS, I produced biodegradable polymer blends by blending thermoplastic starch with poly(butylene-adipate-co-terephtalate) (PBAT) that is also biodegradable and reinforcing it with layered silicates [L6]. I found that incorporated bentonite nanoparticles tend to migrate to the interfacial areas of the components, thus increasing compatibility. This manifests itself in the improved mechanical properties of the biodegradable blends.

Conventional petrochemical polymer-based nanocomposites

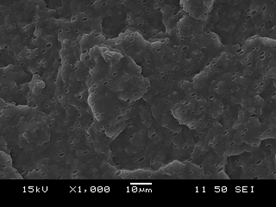

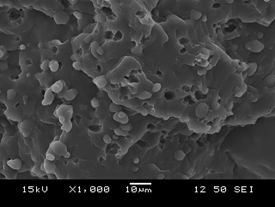

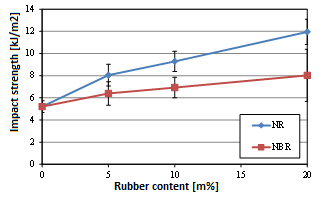

For my research with petrochemical-based polymers, I used polypropylene (PP) and polyamide 6 (PA-6) as matrices. As reinforcement I incorporated a synthetic alumina-based particle called boehmite [L7]. To compensate the toughness loss caused by the presence of boehmite, I also added rubbers of two different types into the composite system. One of the rubbers I used was natural rubber (NR), while the other one was a synthetic acrylonitrile-butadiene-rubber (NBR). This way I was also able to compare additives from renewable resources with additives of synthetic origins. I showed that boehmite greatly increased the stiffness of PP, although at the cost of decreased toughness. Strength in the meanwhile did not change significantly. The toughness loss was successfully compensated with the addition of rubber. The different types of rubbers had different effects on toughness, which could also be related to their origin. Natural rubber (Fig. 6/a) was present as particles of much smaller sizes (600-900 nm) than NBR (2-8 m) (Fig. 6/b). Most likely, this is the reason for the higher toughness of NR-toughened PP (Fig. 6/c).

(a) (b)

(c)

Figure 6: Natural (a) and synthetic (b) rubber dispersion in polypropylene, and their effect on impact strength (c)

Expected impact and further research

Using my research results a suspension-assisted melt compounding technique can be developed, which can be implemented easily and fast in industrial practice, where extrusion compounding is widely used. The introduction of reinforcement and toughener additives in the same step allows the tailoring of the properties of thermoplastic nanocomposites, thus increasing their stiffness, strength and toughness at the same time. There are also other huge benefits of water-assisted techniques not discussed here. The incorporation of nanosized particles, for example, in the usual way (feeding in dry powder form), is associated with possible severe health hazards not researched yet. This can also be circumvented with the use of the suspension technique.

Publications, references, links

Own publications

[L1] J. Karger-Kocsis, Á. Kmetty, L. Lendvai, S. Drakopoulos, T. Bárány:

Water-Assisted Production of Thermoplastic Nanocomposites: A Review. Materials

8, pp. 72-95 (2015), IF=2,728

[L2] L. Lendvai, J. Karger-Kocsis, Á. Kmetty, S. Drakopoulos:

Production and characterization of microfibrillated cellulose reinforced

thermoplastic starch composites, Journal of Applied Polymer Science 133, 42397

(2016), IF=1,860

[L3] S. Drakopoulos, Á. Kmetty, L. Lendvai, J. Karger-Kocsis, G.C.

Psarras: Thermoplastic starch modified with microfibrillated cellulose and

natural rubber latex: A broadband dielectric spectroscopy study, Carbohydrate

Polymers 157, pp. 711-718 (2017), IF=4,811

[L4] L. Lendvai, Á. Kmetty: Természetes növényi latex és

mikro-fibrilláris cellulóz termoplasztikus keményítőre gyakorolt hatásának

vizsgálata (in Hungarian), Polimerek 1, pp. 113-117 (2015)

[L5] L. Lendvai, Á. Kmetty, J. Karger-Kocsis: Preparation and

properties of thermoplastic starch/montmorillonite nanocomposites, Materials

Science, Testing and Informatics VIII 885, 129-134 (2016)

[L6] L. Lendvai, J. Karger-Kocsis, A. Apostolov: Characterization of

layered silicate-reinforced blends of thermoplastic starch (TPS) and

poly(butylene adipate-co-terephthalate), Carbohydrate Polymers 173, pp.

566-572 (2017), IF=4,811

[L7] J. Karger-Kocsis, L. Lendvai: Polymer/boehmite nanocomposites: A

review. Journal of Applied Polymer Science, Accepted Manuscript (2017),

IF=1,860

References

1] L.A. Utracki: Clay-Containing Polymeric Nanocomposites; Rapra Technology Limited: Shawbury, Shropshire, UK (2004)

[2] S. Kalia; B.S. Kaith, I. Kaur: Cellulose Fibers: Bio- and Nano-Polymer Composites; Springer: Berlin, Germany (2011)

[3] G.H. Michler, F.J. Baltá-Calleja: Nano- and Micromechanics of Polymers; Hanser: Munich, Germany (2012)

[4] H. Hargitai: Polimer nanokompozitok (in Hungarian), in Fejezetek nemfémes anyagok legújabb járműipari kutatási területeiből. Széchenyi István Egyetem, Győr, Hungary, pp. 112-141, ISBN 978-615-5391-36-1 (2015)

[5] S. Thomas, K. Joseph, S.K. Malhotra, K. Goda, M.S. Sreekala: Introduction to Polymer Composites, Polymer Composites 1. (2012)

[6] N. Soykeabkaew, N. Laosat, A. Ngaokla, N. Yodsuwan, T. Tunkasiri: Reinforcing potential of micro- and nano-sized fibers in the starch-based biocomposites. Composites Science and technology 72, pp. 845-852 (2012)