|

BMe Research Grant |

|

Oláh György Doctoral School (Chemistry and Chemical Engineering Sciences)

Department of Applied Biotechnology and Food Science

Supervisor: Dr. Béla Sevella

Technological optimization of a biorefinery

Introducing the research area

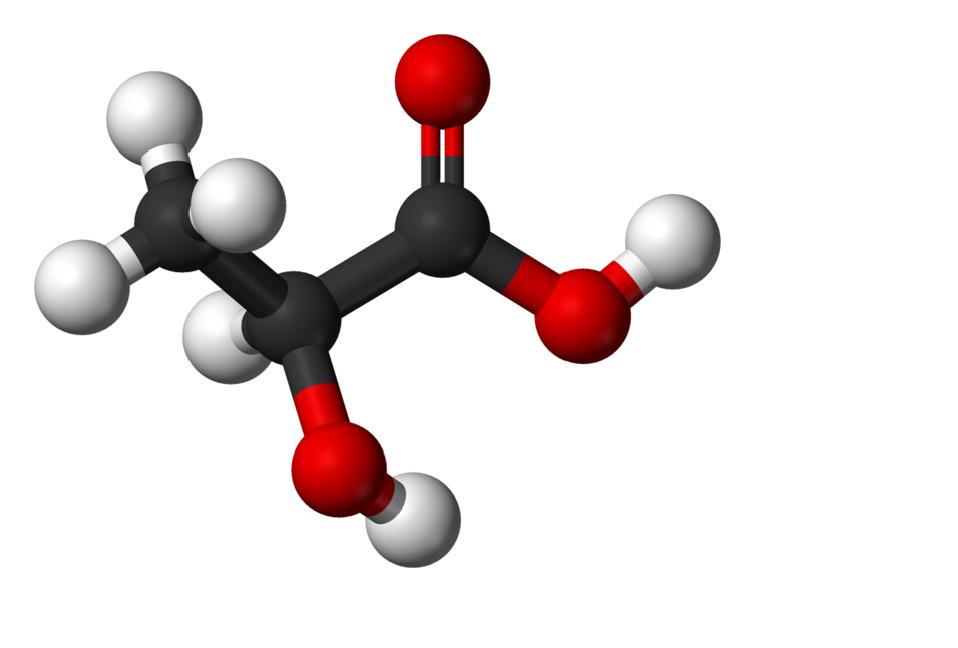

I participate in

the design of a green chemical unit called biorefinery based on renewable raw

materials. The raw material of this plant can be crops (e.g. wheat, sweet

sorghum), while its main product is lactic acid, a platform compound with

versatile application. The planned unit can replace the previous

petrochemistry-based and harmful technologies, since lactic acid is the starting

material of several other substances such as biosolvents (ethyl lactate, butyl

lactate), preservatives (lactate salts) or biodegradable plastics (poly lactic

acid).

I participate in

the design of a green chemical unit called biorefinery based on renewable raw

materials. The raw material of this plant can be crops (e.g. wheat, sweet

sorghum), while its main product is lactic acid, a platform compound with

versatile application. The planned unit can replace the previous

petrochemistry-based and harmful technologies, since lactic acid is the starting

material of several other substances such as biosolvents (ethyl lactate, butyl

lactate), preservatives (lactate salts) or biodegradable plastics (poly lactic

acid).

Brief introduction of the research place

The Fermentation

Pilot Plant Laboratory (F-labor) of the Department of Applied

Biotechnology and Food Science gives place to my researches. The profile of this

research group is to realize biotechnological researches from laboratory to

pilot scale: utilization of biodiesel by-products; production of a viral

preparation against Fire blight; development of a starch-based biogas and

bioethanol technology; recombinant protein expression by yeast cells;

fermentative itaconic acid production; development of a lactic acid producing

technology based on wheat and sweet sorghum.

The Fermentation

Pilot Plant Laboratory (F-labor) of the Department of Applied

Biotechnology and Food Science gives place to my researches. The profile of this

research group is to realize biotechnological researches from laboratory to

pilot scale: utilization of biodiesel by-products; production of a viral

preparation against Fire blight; development of a starch-based biogas and

bioethanol technology; recombinant protein expression by yeast cells;

fermentative itaconic acid production; development of a lactic acid producing

technology based on wheat and sweet sorghum.

History and context of the research

Researches on lactic acid fermentation have several decades of history in

global sense and at our department as well. In the 90s our fermentation group

was involved in the topic of biological lactic acid production by the former Nitrokémia Co., and this cooperation resulted in a feasibility study of a lactic

acid plant.

In 2006, the need for developing a fermentative lactic acid technology arose

again through the commission of the new Nitrokémia Co. and we started our researches in the form of an Estonian

collaboration (Nordbiochem LLC). The raw material of the planned lactic acid plant is wheat, grown in

large quantities in Hungary and possessing high starch content which can be an

appropriate raw material for first generation technologies of bioproducts. The

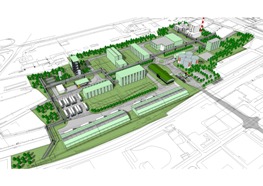

goal of this project is to build a biorefinery

capable of processing 100 thousand tons of wheat a year. In close collaboration

with our department, the project company (Hunest Biorefinery Ltd.) started the

technological design of the plant destined to Balatonfűzfő and commenced writing the

detailed feasibility study.

The need for fermentation products and the utilization of biomass brought to life our new consortial project, as well. In 2008, our project entitled "A cukorcirok integrált mezőgazdasági termelési, tárolási, feldolgozási és logisztikai rendszerének kidolgozása" (Development of an integrated agricultural production, storage, processing and logistic system to sweet sorghum) won the support of the National Office for Research and Technology, hence during the period of 2009–2011 we have the opportunity to participate in the planning of a sweet sorghum-based biorefinery producing lactic acid as one of the main products.

Aim of the research

My research primarily points at the technological development of lactic acid

fermentation in the framework of this biorefinery project. Our global target is

finding a technological solution applicable to both raw materials and capable of cost-effective production at the same time, and integrating further producing

units based on lactic acid so that the resulting complex can become a third phase

biorefinery. This type of plant flexibly adapts to market needs and disposable

raw materials, while its energy consumption required for the production can be partly ensured from by-products and wastes, by burning or processing them to biogas.

The aim of our researches on fermentation technology is to find an effective and

cheap solution, starting from two different raw materials, and examining other

technological parameters besides fermentation medium and finally, to scale-up this

optimized technology to pilot plant scale.

Methods

In a broad sense, fermentative production means a biological reaction, where

the desired product (compound) is created from mostly biological raw materials

(biomass) by one or more microorganisms or by their cell components. This means

that the main aspects of lactic acid (product) production are raw materials

(substrate), producing microorganisms and required

technology.

In bacterial lactic acid fermentations, cells produce energy during lactic

acid formation in the form of ATP for their own purposes using

carbon sources (sugars). For bacterial growth and to build cell components, cells mainly

need nitrogen sources, whereas only a small part of carbon sources is used up for this purpose.

Consequently, the essential steps of lactic acid fermentation are as follows,

-

selection of appropriate microbe: isolation, screening, strain development (genetically)

-

examination of nutrient needs for the selected strain: carbon, nitrogen, micro-component sources

-

qualitative and quantitative optimization of raw materials according to bacterial needs: medium optimization

-

selection of the appropriate pre-treatments and fermentation techniques

-

examination of technological parameters of fermentation done on optimized medium: pH, temperature etc.

-

scale-up of the developed procedure

These tasks may be associated with other problems to be solved in the field of technological developments:

-

selection of raw materials (e.g. appropriate type of sweet sorghum)

-

preparation, fractionation and pre-treatment of raw materials

-

solutions of storage issues of the raw materials

-

supply or in-house production of medium supplements

-

computer simulation and economical evaluation of the experimentally developed techniques

According to the steps mentioned above my research involved the following topics:

-

Experiments on a medium previously optimized by our research group, called Lac-2, with glucose as carbon source:

-

selection of a mesophilic bacterium strain

-

parallel fermentation experiments

-

scale-up to 250 L

-

Technological developments starting from wheat as raw material:

-

medium optimization

-

parallel application of starch hydrolysis and lactic acid fermentation

-

Technological developments starting from sweet sorghum as raw material:

-

examination of sweet sorghum types

-

storage and sugar preservation of sweet sorghum juice and chaff

-

medium optimization

-

Examination of nutrient needs of the used bacterium strain:

-

vitamin and amino acid needs

-

determination of optimal rate for carbon/nitrogen/micro-component sources

-

Effect of pH-regulation and temperature on lactic acid production

-

Development of a lactic acid producing technology based on thermotolerant strain:

-

screening of thermotolerant bacteria

-

nutrient needs of a thermotolerant bacterium

-

use of the selected strain on wheat or sweet sorghum-based media (in laboratory scale)

-

Alternatives to producing yeast extract as supplement for lactic acid fermentation:

-

yeast fermentation on the cellulose and hemicellulose fraction of sweet sorghum bagasse

-

yeast fermentation on sweet sorghum juice

-

computer simulation and economic evaluation of these alternatives

Results

My research results can be summarized as follows,

- Successfully scaled up a classic, batch lactic acid fermentation process

up to 250 liters, on a previously optimized medium, with glucose as carbon

source, using a mesophilic lactic acid bacterium.

-

Optimized a wheat flour-based medium, using its saccharified starch content as carbon source, a part of its protein content (gluten and water soluble proteins) as nitrogen source and a minimal amount of yeast extract (YE) as micro-component source.

-

Compared advantages of simultaneous saccharification and fermentation (SSF) and separate hydrolysis and fermentation (CHF) techniques, and successfully optimized duration of separate hydrolysis before fermentation in a combined hydrolysis and fermentation technique (CHF).

-

Optimized a sweet sorghum juice-based medium, using its sugar content as carbon source, added gluten (wheat proteins) as nitrogen source and a minimal amount of yeast extract (YE) as micro-component source.

-

According to the results of these optimization experiments, I determined the nitrogen and micro-component need of the strain used at a given carbon source level, and defined the essential vitamins and amino acids. Based on the results, I worked out an optimization process (that resulted in a patent application).

- Investigated the pH and

temperature dependence of the strain, and developed a combined pH-regulation

technique, jointly using calcium carbonate and ammonium

hydroxide as pH-regulating agents.

- I selected a thermotolerant lactic acid bacterium and started determining its nutrient needs and its adaptation to both media mentioned above.

-

Based on these results, I started computer simulation and economic evaluation of the biorefinery's processes (lactic acid fermentation, in-house yeast extract production on sweet sorghum bagasse or juice).

Expected impact and further research

Utilization of the fermentation process(es) developed can be realized in two running projects.

Until the end of 2011, we participate in the

development of an agro-industrial model in the frames of the project entitled "A cukorcirok integrált

mezőgazdasági termelési, tárolási, feldolgozási és logisztikai rendszerének

kidolgozása" (Development of an integrated agricultural production, storage,

processing and logistic system for sweet sorghum), using the results of our researches on

lactic acid fermentation and yeast extract production. The indirect aim of this

work (supported by NKTH) is to create an R&D and innovative

background capable of continuously supporting the production and expanding

the consumption.

The long-term aim of a prospective biorefinery

to be established in Balatonfűzfő (by Nitrokémia Co.) is to produce a

high-quality and cost-effective platform compound (lactic acid), which can be an

appropriate raw material for the production of a biodegradable plastic (PLA),

thus creating an environmentally friendly, green chemical unit.

Publications, references, links

Related publications

Patent

- Hetényi K. Zs., Németh Á., Sevella B., Kovács L. P., Bodnár Zs.: Eljárás haszonnövények fermentációs felhasználására tejsav és származékainak előállítása céljából, P1000061 (patent application: January of 2010)

Papers

- K. Hetényi, K. Gál, Á. Németh, B. Sevella: Use of sweet

sorghum juice for lactic acid fermentation: preliminary steps in a process

optimization, Journal of Chemical Technology and Biotechnology 85 (2010)

872–877

- K. Hetényi, Á. Németh, B. Sevella: First steps in the development of a wheat flour-based lactic acid fermentation technology. Culture medium optimization, Chemical and Biochemical Engineering Quarterly (2009) under publication (publication is expected: 2010/2)

- K. Hetényi, Á. Németh, B. Sevella: Examination of medium supplementation for lactic acid fermentation, Hungarian Journal of Industrial Chemistry 36 (2008) 49–53

- K. Hetényi, Á. Németh, B. Sevella: Researches on White Biotechnology, Hungarian Journal of Chemistry 3 (2008) 102–106

Oral Presentations

- Hetényi K., Németh Á., Sevella B.: Tejsavbaktérium tápanyagigényének technológiai szempontú vizsgálata, Műszaki Kémiai Napok ’10, Veszprém, 27–29 April 2010

- Hetényi Kata: Biofinomító technológiáinak optimálása, Szent-Györgyi Albert Szakkollégium, A Biotechnológia a biológia, a kémia és a mérnöki tudományok találkozása c. konferencia, Budapest, 20 March 2010

- Hetényi K.: Biofinomító technológiáinak optimálása, Vegyészmérnöki és Biomérnöki Kar Oláh György Doktori Iskolájának VII. konferenciája, Budapest, 4 February 2010

- K. Hetényi, Á. Németh, B. Sevella: Lactic acid fermentation on wheat flour via SHF and SSF technology, 2nd Central European Forum for Microbiology (CEFORM), Keszthely, 7–9 October 2009 (English), abstract: Acta Microbiologica et Immunologica Hungarica 56 (2009) 167–168

- K. Hetényi, Á. Németh, B. Sevella: Tejsav-fermentációs tápközeg vitamin kiegészítése, Magyar Mikrobiológiai Társaság 2008. évi Nagygyűlése, XI. Fermentációs Kollokvium, Keszthely, 15–17 October 2008, abstract: Acta Microbiologica et Immunologica Hungarica 56 (2009) 36

- K. Hetényi, Á. Németh, B. Sevella: Tejsav fermentációs tápközeg kiegészítésének vizsgálata, Műszaki Kémiai Napok ’08, Veszprém, 22–24 April 2008

- K. Hetényi, Á. Németh, B. Sevella: Tejsavtermelő technológia fejlesztése, Műszaki Kémiai Napok ’07, Veszprém, 25–27 April 2007

Posters

- K. Hetényi, K. Gál, Á. Németh, B. Sevella: Use of sweet sorghum juice for lactic acid production, Műszaki Kémiai Napok ’09, Veszprém, 21–23 April 2009; Vegyészmérnöki és Biomérnöki Kar Oláh György Doktori Iskolájának IV. konferenciája, Budapest, 4 February 2009

- K. Hetényi, B. Sevella: Cost effective lactic acid production on wheat flour, Pannon Mérnöknapok, Veszprém, 27–28 February 2008; Vegyészmérnöki és Biomérnöki Kar Oláh György Doktori Iskolájának V. konferenciája, Budapest, 8 February 2008

- K. Hetényi, Á. Németh, B. Sevella: Researches on Renewabe Resources at BUTE ABFS F-labor, 5th Croatian Professional and Scientific Conference on Biotechnology with International Participation, Stubicke Toplice, 9–10 May 2007

Links