|

|

BMe Research Grant |

|

Kandó Kálmán Doctoral School of Transportation and Vehicle Engineering

BME KJK, Department of Automotive Technologies

Supervisor: Dr. Zöldy Máté

Application of Artificial Intelligence in Fuel Technology

Introducing the research area

The need for mobility in modern society is increasing dramatically. Sustainable servicing of this demand can only be achieved through new technologies. An example of this is electrification, which we can easily observe in new passenger cars. However, electrification offers a viable solution only for a single segment of mobility, and many other forms of transportation do not benefit from it. Road freight, air, and water transportation, as well as heavy machinery, are expected to rely on liquid fuels as the only realistic technological solution in the long term, due to their numerous advantages. Therefore, there is a need to develop new "advanced fuels" that can be used with a sustainable level of environmental impact based on their production method and composition. The design of these new compounds and mixtures often requires complex physical and chemical simulations, as well as a multitude of tests using expensive compounds. These costly and time-consuming processes hinder the marketability of advanced fuels. To improve the cost and time efficiency of developments, it is advisable to leverage the opportunities provided by artificial intelligence (AI). With the help of AI, we can replace traditional physical and chemical models with empirical models that, after a learning process, can quickly provide results of similar accuracy to simulations. In my research, I am developing artificial intelligence-based methods that allow for rapid and cost-effective prediction of key combustion, emission, and efficiency parameters during the real operation of the engine based on the properties of the applied compounds.

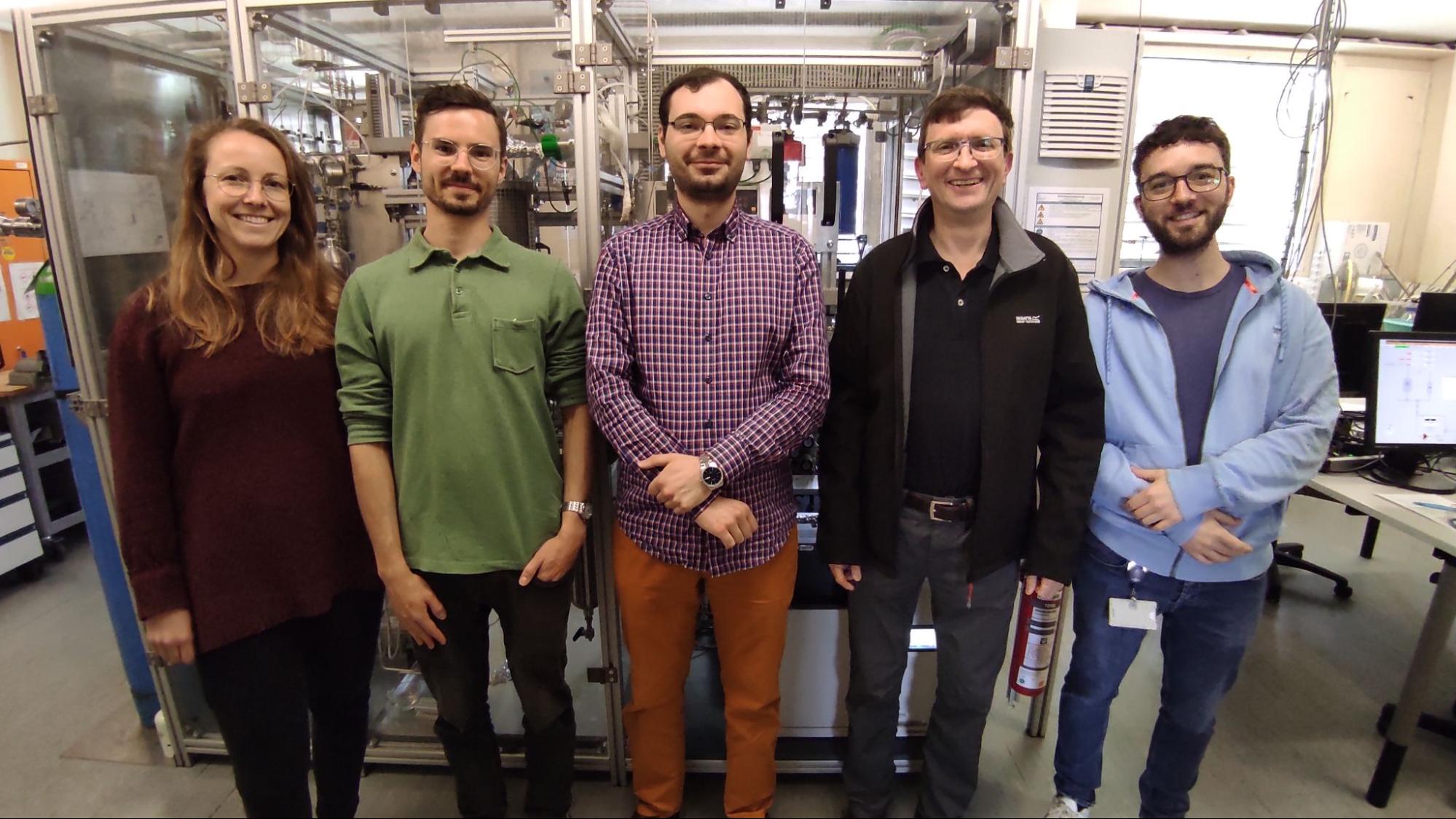

Brief introduction of the research place

I perform my industrial cooperative doctoral research, supported by AVL Hungary Ltd., at the Innovative Vehicle Technologies Competence Center, inaugurated in 2023 through the cooperation of Bosch and BME. For my measurements, I use the engine dynamometers of the BME Department of Automotive Technologies. The BME Faculty of Mechanical Engineering provides me with the necessary equipment for measuring the viscosity and density of the fuels. The Institute of Catalysis Research and Technology at Karlsruhe Institute of Technology (KIT) assists me in the analytical examination of fuels. Additionally, the Institute provides various fuels for the engine dynamometer tests, making this international research collaboration an essential component of my work.

Figure 1. Left:

Innovative Vehicle Technologies Competence Center;

Right:

Visiting the Institute of Catalysis Research and Technology at KIT

History and context of the research

The technological diversity in transportation contributes to each sector of mobility utilizing the best solutions available. In many areas, liquid motor fuels provide the only realistic option for energy storage [S1]. Even the leading results in battery research, such as the new lithium battery from KIT (560 Wh/kg = 2.01 MJ/kg), only achieve a fraction of the energy density of diesel fuel (~43 MJ/kg). This would not only lead to a decline in competitiveness but could also hinder the basic function of the powered machines in numerous fields. The requirement for rapid delivery of large amounts of electrical energy also presents additional technological limitations. In the short and medium term, advanced fuels offer a simple solution for achieving climate-neutral transportation, even in the case of passenger vehicles, as the complete transition to electric power will take decades (especially outside of Europe). By utilizing existing infrastructure and proper fuel composition, the environmental impact of vehicles already in operation can be significantly reduced. In the long term, fuels are expected to remain dominant only in transportation sectors that require high energy density, as mentioned earlier. Advanced fuels already exist, but due to their cost and various technological drawbacks, apart from a few exceptions (e.g., HVO), they have not yet become competitive in the market. The methods I am developing in my research accelerate the market entry process, thus enabling a real solution to the problem.

The research goals, open questions

The aim of my research is to develop an AI-based preliminary fuel designer tool that can provide accurate predictions of engine operation within the engine's useful operating range, as well as to develop some associated efficiency-enhancing procedures. These empirical methods aim to replace the current physical and chemical models at least partially. The fast computations of AI enable rapid impact assessment of various compounds and straightforward determination of research directions. However, training AI requires a representative training dataset, which can be costly to generate based on real measurement data. If the dataset or the model-building process is incorrect, the training will be slow, and the resulting AI models will be inaccurate. Therefore, I also aim to develop a methodology that supports the fast and cost-effective creation of representative datasets and the creation of rapidly learning and accurate AI models.

Methods

The task to be solved by the AI can be mathematically formulated as a multi-input and multi-output regression problem. After analyzing numerous AI technologies in the literature, I have concluded that multilayer perceptron (MLP) artificial neural networks (ANN) are the best for my tasks [1,2,3,4].

For the tool, I will generate the training dataset using our department's Cummins engine and our measurement systems and computational methods described in our previous works [S2, S3, 5]. The initial step is to gain experience with training MLP networks using engine data. In this step, I need to establish the efficiency of my research workflow by developing various automated measurement, measurement evaluation, and MLP network generation procedures to turn my data into results with “a simple click”. Additionally, the engine dynamometer must be prepared for conducting the necessary measurements with small fuel samples.

Once this is accomplished, I can proceed with the first objective in the logical sequence: developing the methodology for cost-effective dataset creation and rapid and accurate AI model building. Up to this point, there is no need for the use of special fuel compositions, as the experiments can be conducted with commercial B7 diesel.

The next phase involves examining fuel blends composed of different compounds. It is important to have precise knowledge of the chemical composition, as this will be one of the inputs to the neural networks, therefore diesel cannot be a blending component. The properties of the components will be determined through measurements, while the properties of the blends will be determined using mixing rules, to increase cost-effectiveness. At first, I will conduct fuel tests without AI to assess the effectiveness of the engine dynamometer modifications and gain experience with alternative fuels and their effects on engine performance.

Once the conditions for safe and precise measurements are established, I will create the training dataset and AI models using the methodology I have developed to ensure cost-effectiveness and accuracy. Based on the models and supplementary procedures, I will create the final tool that can predict combustion, emissions, and efficiency parameters related to fuel properties within the engine's useful operating range. I will then validate the tool's operation by performing predictions on the behavior of new fuel compositions and comparing them with real measurement data.

Results

Currently, I am halfway through my research. With my engine dynamometer developments, fuel tests can be efficiently conducted. In the original daily tank system's pipeline, approximately 3 liters of buffer fuel was required, which was not acceptable due to the expensive compounds involved. With my new supplementary fuel system, this has been reduced to around 0.3 liters. I have developed a measurement procedure that includes optimized warm-up and operating point measurement phases, allowing for significant fuel savings [S4]. For this procedure, I have created an automated measurement evaluation algorithm and a program for generating MLP neural networks with various configuration options, ensuring the speed of the research process.

I have conducted several experiments to assess the prediction accuracy of MLP networks [S5]. Using manual methods, I was able to create relatively accurate models, but improvements in accuracy and runtime were necessary. Based on my experiences, I have developed a methodology that enhances the time and cost efficiency of training MLP networks with engine-related data. To achieve this, I obtained a high-resolution dataset containing 6277 different operating points with varying speeds, torques, and EGR rates [S4]. Using this dataset, I explored numerous literature methods for training the networks, evaluating their accuracy, and selecting relevant input parameters and network architectures. Based on the results, I established a general process that guarantees the rapid and accurate training of MLP networks for this specific mathematical problem. Additionally, I created a method to determine the minimal resolution required for the motor dynamometer measurements. By breaking down the high-resolution dataset into smaller subsets and analyzing the models generated from these subsets, I created a methodology package that ensures both accuracy and efficiency while minimizing fuel consumption during the generation of representative datasets for the final tool.

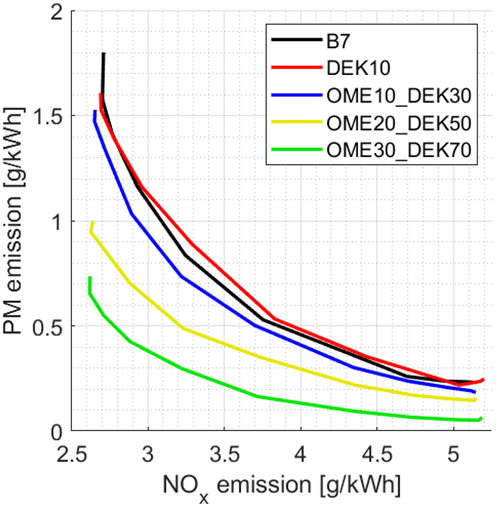

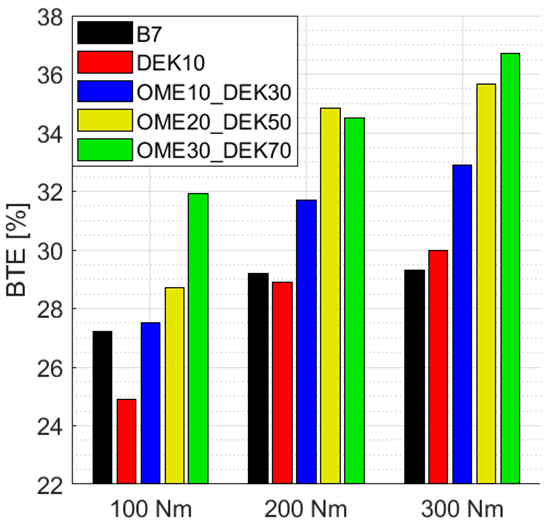

The next phase involves the creation of the fuel designer tool. As part of the knowledge acquisition process, I conducted multiple experiments using various fuels. I focused on oxygenated compounds, as they improve the raw emissions of diesel engines [S6]. Using oxymethylene ether (OME) obtained from the Karlsruhe Institute of Technology (KIT) [6,7,8,9], I successfully reproduced the characteristic results reported in the literature [S3]. However, the compound has several properties that deviate significantly from the EN590 standard for diesel. To enhance the fuel properties, I created scientifically novel B7-OME-Decanol ternary blends, which incorporate 1-decanol [10] to enhance mixture properties. The addition of decanol successfully improved the fuel properties as expected [S7].

Figure 2. Application of Decanol and OME - Left: improved NOx-PM trade off; Right: improved brake thermal efficiency.

As part of the final phase and further preparations, I am currently working on mixing rules and compound property prediction. The Karlsruhe Institute of Technology conducted the analysis of three of my blending components and twelve of my blends. With the results obtained, I can verify the accuracy of various mixing rules. Additionally, in collaboration with KIT, I am developing an artificial intelligence-based algorithm for compound property prediction. This algorithm is capable of predicting the physical properties of designed compounds based on molecular structure and other parameters.

Expected impact and further research

As part of the international collaboration with KIT, I will conduct further engine dynamometer testing of specialized compounds, and we will finalize the compound property prediction tool. Following that, I will generate the final training dataset using a variety of blends. From this dataset, I will create an AI-based pre-design tool, which will then be validated through real-world usage. The developed methods and algorithms will be directly applicable in multiple stages of advanced fuel design. Compound property prediction can be utilized prior to the synthesis of new materials, while the preliminary fuel designer tool can assist in determining the fuel composition. The AI-based methods created will serve as advantageous substitutes or complements to the currently used physical and chemical models, enhancing efficiency and cost-effectiveness.

Publications, references, links

List of corresponding own publications.

[S1] Virt M., Zöldy M. Folyékony hajtóanyagok fejlesztési tendenciái, Közlekedés és Mobilitás, Közlekedéstudományi Intézet, 2022, 1(1), 14.

[S2] Virt, M.; Granovitter, G.; Zöldy, M.; Bárdos, Á.; Nyerges, Á. Multipulse Ballistic Injection: A Novel Method for Improving Low-Temperature Combustion with Early Injection Timings. Energies 2021, 14, 3727. https://doi.org/10.3390/en14133727

[S3] Virt M., Arnold U. Investigating the Effects of Oxymethylene Ether in a Commercial Diesel Engine, Cognitive Sustainability, 2022, 1(3).

[S4] Virt, M. Zöldy, M. “Artificial Neural Network Based Prediction of Engine Combustion and Emissions from a High-Resolution Dataset”, 1st IEEE International Conference on Cognitive Mobility, 2022

[S5] Virt, M. Zöldy, M. “Mesterséges neurális hálózatok motortechnikai alkalmazása”, XXX. Nemzetközi Gépészeti Konferencia, 2022

[S6] Virt, M. Zöldy, M. “A tüzelőanyagból és a beszívott levegőből származó oxigénmennyiség hatásai”, XXXI. Nemzetközi Gépészeti Konferencia, 2023

[S7] Virt, M. Horváth, L. Zöldy, M. “Density and viscosity measurements for diesel-decanol-oxymethylene ether blends”. Angolan Mineral, Oil & Gas Journal, v. 4, n. 4, p. 1–5, 8 Apr. 2023.

Table of links.

List of references.

[1] I. Goodfellow, Y. Bengio, A. Courville: Deep Learning, MIT Press, 2016

[2] D. P. Kingma, J. L. Ba: ADAM: A Method for Stochastic Optimization. https://arxiv.org/abs/1412.6980, 2018

[3] T. Tieleman, G. Hinton: Lecture 6.5-rmsprop: Divide the gradient by a running average of its recent magnitude, COURSERA: Neural Networks for Machine Learning, 2012

[4] G. R. Kannan, K. R. Balasubramanian and R. Anand, „Artificial Neural Network Approach to Study the Effect of Injection Pressure and Timing on Diesel Engine Performance Fueled with Biodiesel,” International Journal of Automotive Technology, vol. 14, pp. 507–519, 2013.

[5] Nyerges, Á.; Zöldy, M. Verification and Comparison of Nine Exhaust Gas Recirculation Mass Flow Rate Estimation Methods. Sensors 2020, 20, 7291. https://doi.org/10.3390/s20247291

[6] Haltenort, P.,Hackbarth, K., Oestreich, D., Lautenschütz, L., Arnold, U., Sauer J. (2018). Heterogeneously catalyzed synthesis of oxymethylene dimethyl ethers (OME) from dimethyl ether and trioxane. Catalysis Communications. 109, 80–84. DOI: https://doi.org/10.1016/j.catcom.2018.02.013