|

|

BMe Research Grant |

|

Géza Pattantyús-Ábrahám Doctoral School of Mechanical Engineering

BME GPK, Department of Polymer Engineering

Supervisor: Dr. Czigány Tibor

Health monitoring of carbon fibers in composite structures

Introducing the research area

Composite structural materials, especially carbon fiber reinforced polymer matrix composites, are finding their application increasingly due to their high strength at low density, good chemical resistance, and strength properties that can be tailor-made to specific loads. In many industries that use composites (e.g. automotive, energy), the main direction of development targets weight reduction. In addition to the use of lower specific weight materials, the weight reduction of a structure can be achieved by combining functions and creating multifunctional components. In my dissertation, I aimed to develop a multifunctional material that uses the electrical properties of carbon fiber used as a reinforcing fiber for structural state monitoring.

Brief introduction of the research place

I carry out my research at the Department of Polymer Engineering, whose laboratory is accredited and audited according to the ISO 9001 quality assurance and ISO 14001 environmental management systems. My topic is related to several projects (OTKA K 120592, NVKP_16-1-2016-0046) and to the work of the MTA–BME Research Group for Composite Science and Technology. The Department publishes one of Hungary’s highest impact factor Open Access journal, the Express Polymer Letters.

History and context of the research

The multifunctional use of carbon fiber reinforced polymer composites, including the exploitation of secondary functions based on the electrical properties of the reinforcing fiber, is a widely researched topic, with numerous application examples in the literature. The secondary function of the carbon fiber can be, for example, resistance heating, which enables the composite product to be heated locally, so that crosslinking, welding, de-icing (Figure 1) or self-healing can be achieved [1, 2].

Figure 1 Multifunctional aircraft wing made of carbon fiber reinforced polymer composite. In addition to the reinforcing function, the carbon fiber can also be used for de-icing

In a specific arrangement, the carbon fiber composite is suitable for electrical shielding [3], energy storage [4], actuation [5], and as a sensor for structural state monitoring [6]. Structural materials that sense their own environment are the first step towards intelligent materials, for which there is a growing demand in the world of Industry 4.0 and autonomous vehicles. I compiled an article on the multifunctional use of carbon fibers and the possible secondary functions, where I systematized the application examples by the raw materials and auxiliaries they require, and I introduced a new schematic notation system [FN1].

The research goals, open questions

Carbon fiber reinforced components (e.g., aircraft wing, wind turbine blade) are typically safety critical, i.e. their failure can have catastrophic consequences. Recognizing this, the main goal of my research is to provide the carbon fiber with a secondary function besides its structural task. Based on my literature review, I narrowed my goal: to study and develop a condition monitoring procedure using the electrical properties of carbon fiber. This goal was broken down into the following subtasks:

• development of a measurement method and arrangement for the investigation of the electrical resistance of carbon fibers used as composite reinforcing materials,

• for which I examine the possibilities of connecting the carbon fiber bundle to the electric circuit, and the current path in the fiber bundle and in the composite specimen,

• and I analyze the effect of the properties of the fiber bundles used as reinforcement (geometric, mechanical) and the measurement conditions (temperature, humidity, current) on measurement accuracy and reproducibility in the case of sensory use,

• then I will explore the correlations between the change of electrical resistance of the carbon fiber bundle and the deformation and failure of the composite under various mechanical tests (tensile, bending, fatigue, impact tests).

Based on the results, I demonstrate continuous condition monitoring on a real composite structure by measuring the resistance of the carbon fiber bundle, which allows for the prediction of a fracture due to fatigue or overload, or the immediate detection of a sudden failure.

Methods

I used various test specimens and measurement layouts for my experiments. At the beginning of my research, I examined the electrical properties of the elemental carbon fiber separately, and then analyzed the electric current path in a commercially available package, in the form of roving (also called as bundle). Within the fiber bundle, the individual fibers are not infinite in length, but fragmented, which affects the resistance of the fiber bundle, leading to inhomogeneous current density.

For my later experiments, I prepared composite specimens. These mechanical tests require standard specimen size, which was achieved by making a composite plate from the electrically insulating fiberglass reinforcement, in which a bundle of carbon fibers at a predetermined location was inserted during manufacture. The ends of the carbon fiber bundle were left free for joining them with the electrical connectors I developed, and thus allowing me to connect them to a circuit.

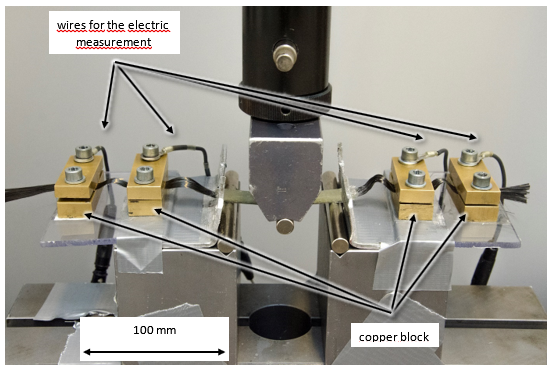

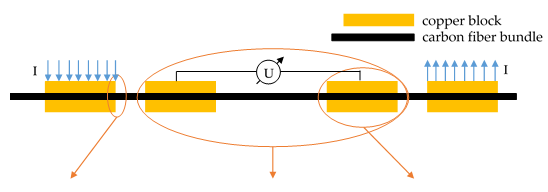

The electrical resistance was measured on the composite specimens in a four-wire arrangement, of which one pair of wires served for current input, and the voltage drop between two points was measured on a separate pair of wires. From the two values, the resistance of the given carbon fiber bundle can be determined precisely, because the resistances of the measuring instrument and the wires were not included as a source of a permanent fault.

To determine the relationship between the deformation and the resistance of the carbon fiber bundle, I performed tensile tests. During the quasi-static test, I continuously measured the change in the resistance of the carbon fiber, from which the change specific resistance could be calculated, which was then compared with the specific deformation obtained from the elongation measurement.

In my initial measurements and literature search, I found that carbon fiber resistance is affected not only by mechanical load but also by its environment. The effect of ambient temperature and humidity was studied separately in a climate chamber. The test range was determined to extend beyond the typical application ranges of composite components.

Besides the quasi-static measurements, the specimens were loaded dynamically as well. In a three-point bending arrangement, I loaded the samples with cyclic stress until fatigue failure (Figure 2).

Figure 2 Measurement arrangement for three-point cyclic fatigue test

Results

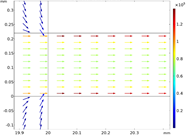

I started my experiments with preliminary ones, during which I determined the longitudinal and transverse specific resistance of the carbon fiber bundle and the effect of the matrix material (as an electrical insulator) on conductivity. I carried out my research in collaboration with the Department of Atomic Physics (Dr. Tamás SARKADI and Csanád Örs BOROS), and based on the preliminary results we created a finite element model (FEM) to study the current conduction environment and the current path in the fiber bundles (Figure 3).

a

b c d

Figure 3 Schematic diagram of four-wire resistance measurement (a), representation of current density vectors in the FEM software (b), longitudinal distribution of current density based on FEM simulation (c), and “current suction” effect of copper mounts used for voltage measurement (d)

Based on the simulation, I developed a method for coupling fiber bundles into an electrical circuit for more homogeneous current density and more accurate resistance measurement. Based on the results, I prepared an article for submission, which I will submit to the IEEE Sensors Journal (IF2019=3.073).

I then verified the functionality of the elongation measurement method based on electrical resistance measurement. A specimen deforms under the force applied to it, and with that the carbon fiber bundle also stretches. Carbon fibers exhibit piezoresistivity, which means that their resistance under deformation changes more than it would result from the pure geometric change. Based on the deformation–resistance change diagram, the carbon fiber can be calibrated as a sensor, and the gauge factor can be determined by analogy with the strain gauges [FN2-4].

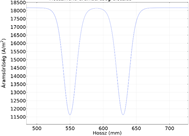

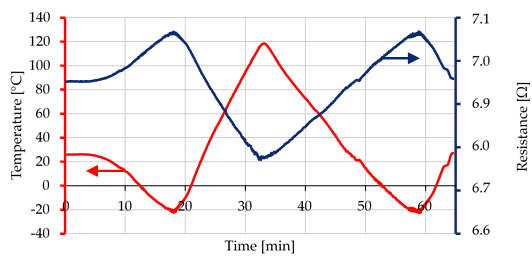

In addition to deformation, the resistance of the carbon fiber bundle is also affected by a number of effects. Environmental factors (temperature, humidity) may change during a measurement, which may introduce a measurement error when using carbon fibers as a strain gauge. I investigated the effect of ambient temperature (Figure 4) and humidity on carbon fiber resistance.

Figure 4 Effect of temperature on the resistance of a reinforcing carbon fiber bundle used as a sensor. The temperature coefficient of the carbon fiber bundle is negative [FN5]

According to my results, with increasing temperature and humidity, the resistance of the carbon fiber decreases, where the effect of temperature is an order of magnitude greater than that of humidity. Therefore, the carbon fiber bundle may be suitable for indicating a change in temperature, on one hand, e.g. the crosslinking of the resin during production or a thermal fatigue can be examined by measuring the resistance of the carbon fibers. On the other hand, when considering strain gauge sensor applications, the effect of temperature must be compensated [FN5].

To research the effect of the test current used in the resistance measurement on the dynamic mechanical properties of the composite specimen, I performed three-point impact bending tests on a specimen with different test currents. The power was connected to the specimen before the impact, and after the impact it was turned off immediately. I also changed the switching time before the shock. From the results, I concluded that the dynamic mechanical properties of specimens decrease under the influence of high current. With the measurement results, I applied for the SEIA2020 conference to be held in Porto, 2020 [FN6].

Expected impact and further research

The actuality of the topic is well illustrated by the fact that my article reviewing and organizing multifunctional application examples was published in a journal with high impact factor, Composites Part B: Engineering (IF = 7.635, D1) and already received many independent references to date (Web of Science (WoS): 32, Elsevier Scopus: 43, Google Scholar: 46). According to the WoS, this publication ranks in the top 1% in the field of materials science based on the number of citations.

I start the last semester of my doctoral training; my short-term research plan includes the full support of the theses. Based on my experiments, I identified numerous possibilities for further development. Of these, I would highlight the applicability study: by designing appropriate signal processing electronics, airplane wings or wind turbine blades could be implemented as intelligent composite products that can continuously monitor their own structural integrity, send an alarm to the operator in the event of failure, and prevent a catastrophic accident.

Publications, references, links

List of corresponding publications

[FN1] Forintos N., Czigany T.: Multifunctional application of carbon fiber reinforced polymer composites: electrical properties of the reinforcing carbon fibers – a short review. Composites Part B - Engineering, 162, 331–343 (2019). 10.1016/j.compositesb.2018.10.098 IF=7.635 D1

[FN2] Forintos N., Czigány T.: Kompozitba épített elektromosan vezető érzékelő. Polimerek, 2, 196–199 (2016).

[FN3] Forintos N., Czigány T.: Üvegszál erősítésű kompozitok deformációjának mérése szénszálak segítségével. in 'OGÉT 2017: XXV. Nemzetközi Gépészeti Konferencia Cluj, Romania. 2017.04.27-2017.04.30.,147–150 (2017)

[FN4] Czigány T., Forintos N., Hegedűs G.: Health monitoring of high-performance polymer composites with multifunctional fibers. in 'ICCM21 Xi'an, China. 2017.08.20-2017.08.25., pp 3153/1–3153/8 (2017)

[FN5] Forintos N., Czigány T.: Reinforcing carbon fibers as sensors: the effect of temperature and humidity. Composites Part A – Applied Science and Manufacturing, 131, article ID: 105819 (2020). 10.1016/j.compositesa.2020.105819 IF(2019)=6.444 D1

[FN6] Forintos N., Czigány T.: Multifunctional carbon fiber reinforced polymer composite structures: reinforcing and sensing. Sixth International Conference on Sensors and Electronic Instrumentation Advances (SEIA' 2020), Porto, Portugal, 23–25.09.2020 (2020).

List of references

[1] Reese J., Vorhof M., Hoffmann G., Böhme K., Cherif C.: Joule heating of dry textiles made of recycled carbon fibers and PA6 for the series production of thermoplastic composites. Journal of Engineered Fibers and Fabrics, 15 (2020) doi:10.1177/1558925020905828.

[2] Pan L., Liu Z., Kiziltas O., Zhong L., Pang X., Wang F., Zhu Y., Ma W., Lv. Y.: Carbon fiber/poly ether ether ketone composites modified with graphene for electro-thermal deicing applications. Composites Science and Technology, 192, article ID 108117 (2020).

[3] Aripin A.B., Yamamoto T., Nishi M., Hayakawa K.: Electromagnetic shielding property of laminated carbon fiber tape reinforced thermoplastics. Polymer-Plastics Technology and Materials, 59, pp 1308-1316 (2020).

[4] Moyer K., Meng C., Mashall B., Assal O., Eaves J., Perez D., Karkkainen R., Roberson L., Pint C.L.: Carbon fiber reinforced structural lithium-ion battery composite: Multifunctional power integration for CubeSats. Energy Storage Materials, 24, pp 676–681 (2020).

[5] Vermes B, Czigany T.: Non-conventional deformations: Materials and actuation. Materials, 13, paper ID: 1383 (2020) doi:10.3390/ma13061383.

[6] Luan C., Yao X., Shen H., Fu J.: Self-sensing of position-related loads in continuous carbon fibers-embedded 3D-printed polymer structures using electrical resistance measurement. Sensors;18, paper ID: 994 (2020). doi:10.3390/s18040994.