|

|

BMe Research Grant |

|

Géza Pattantyús-Ábrahám Doctoral School of Mechanical Engineering

BME GPK, Department of Materials Science and Engineering

Supervisor: Dr. Dobránszky János

Examination of mechanical and corrosion damages of coronary stents

Introducing the research area

Approx. 27, 000 stents per year are implanted in Hungary, and this number has shown a steady upward trend in recent years. The market for coronary stents includes products made from a variety of material qualities and coatings, but apart from comparisons made by manufacturers, there are few sources that compare these devices by examining their mechanical and corrosion damages. The aim of my research is to study the stents and the damage of the coating on the stent during expansion, the effect of the coating on the corrosion properties, as well as the damage under real conditions tested on explanted samples. Additive manufacturing processes, which are gaining more and more ground in the technical field, have also appeared in the field of stent manufacturing, so in line with international trends, I also included the study of additively manufactured devices in my research focusing on traditionally manufactured devices.

Brief introduction of the research place

I conduct my research primarily at the Department of Materials Science and Engineering, BUTE. I carry out my research on additively manufactured stents as part of the DAAD scholarship program at the Ostbayerische Technische Hochschulen in Regensburg. During the research work, close cooperation was established in the field of corrosion with the staff of the Department of General and Physical Chemistry of the University of Pécs, as well as with the PROMATECH laboratory in Košice.

History and context of the research

Cardiovascular diseases are the leading cause of death in Hungary, but the importance of prevention and treatment is not given enough emphasis. The twenty-year history of medical research at the Department of Materials Science and Technology aims to further develop the implants currently in use, increasing their effectiveness. Within cardiovascular disease, vasoconstriction is one of the most dangerous and common diseases, and its most effective treatment is to implant a mesh-like metallic device, the so-called stent. During surgery, the stent is delivered to the narrowed vascular section through the femoral neck or wrist artery using a guide wire and balloon catheter, where it is dilated. After successful implantation, the stent remains in the vessel for the rest of the patient's life, so it is extremely important to study the exact stresses the implant will suffer throughout its lifetime and how they will affect stent performance. Such stresses may include the implantation process itself, mechanical stresses due to vascular movement, and blood-induced corrosion. I began my stents related researches in 2015, examining explanted stents and continued with corrosion measurements. As a student, I conducted several TDK researches on the topic, and in the course of my doctoral research, I delved into the topic of damage assessment based on my previous results and observations.

|

|

|

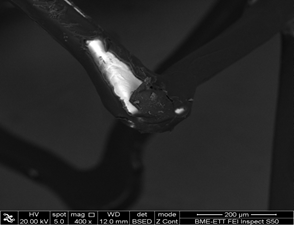

Damages of stent coating on one explanted stent

The research goals, open questions

The aim of the research is to give a real picture of the degradation processes of stents and stent coatings, to make implants made of different materials and manufacturing technologies comparable with the research results. One of the most important topics is to investigate the effect of coatings, to answer when and to what extent is the coating damaged during the life cycle of the implant, and how this affects the corrosion resistance. In my previous research I have also observed the detachment of coating from the surface of the metal, so one of my current objectives is to answer how the adhesion of the coating could be improved. Stents are exposed to the most intense stress during positioning and dilation, and the aim of my research is to understand how the increasing dilation pressure affects the functional properties of stents. A special case of dilation is when another stent is dilated into a previously dilated stent. This raises further questions about the degree of abrasion of the two stents and the corrosive processes that take place in the possibly different two alloys. Research should not ignore plastic stents in addition to metals, as there is a growing demand for degradable implants, and the current state of science suggests that PLLA-based stents are best suited for this purpose.

Methods

Damages to in vivo damaged stents were examined by scanning electron microscopy (SEM) and changes in material composition were analyzed by energy dispersive X-ray spectrometry (EDS). From the raw material and the pattern of the stent the manufacturer could be identified whose product was implanted in the patient, so comparing my measurement results with the catalog data, I can answer if any of the allergen metals (nickel, chromium) has dissolved significantly in the surrounding tissues.

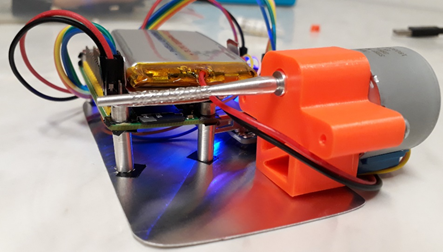

For in vitro, i.e. laboratory tests, I develop test methods suitable for each research purpose. Damages from dilation were examined with a stereomicroscope and SEM. Dilation is carried out in a vessel model that adequately reflects the physiological conditions, because in many in vitro studies the stent is dilated in air or liquid, but then the effect of the vessel wall is disregarded, which in my opinion is not negligible. I observe the degree of coating damage, recoil, expansion shortening, radial load capacity, and several other functional properties on stents dilated with different pressure values. To examine to coating, I used a special holder device developed during my previous research for use with a scanning electron microscope,. The Zeiss EVO MA 10 device at the Department of Materials Science and Engineering is capable of operating in a so-called low vacuum mode, which allows testing plastic samples so that they do not get charged. In backscatter electron detection mode, by analyzing the contrast image with image analysis software, we can obtain a quantifiable value of the degree of coating damage.

I have done research to improve the adhesion of the coating, but in my future research I plan to expand the surface treatment methods used so far, and study the applicability of the electrospinning method for the production of the coating in addition to the traditional immersion technique.

Fatigue testing on dilated stents shows how the stent ribs wear each other upon getting in contact, and when soaked in a phosphate buffer solution or other physiologically similar solution, a corrosion effect can also be observed.

I implement a complex investigation of the degradation process by soaking in additive-made, PLLA-based, stent-like structures in simulated body fluid. On the samples, I not only observe the degradation process, but also examine how the various stent properties, like radial load, change as the soaking time progresses.

Results

In my previous research, I observed that the coatings on the surface of explanted samples were greatly damaged. From the physical simulation of stent implantation I conducted to determine the time of damage formation, I observed that the coating had already ruptured or even detached from the surface of the stent during expansion, which further increased with increasing expansion pressure.

Prototype of the stent holder device

Of the commercially available stents I tested, Fe-Pt-Cr-based stents have the best corrosion resistance, followed by ‘316L’ austenitic stainless steel and then ‘L605’ cobalt-chromium alloy. Examining the effect of the coating on corrosion, I observed that the corrosion resistance of Fe-Pt-Cr based stents has improved by the PVDF-HFP plastic coating, and degraded by the amorphous silicon carbide. The pharmaceutical coating without the plastic bonding layer has no significant effect on the corrosion behavior of the material. No corrosion damage could be observed on the Fe-Pt-Cr stents when potentiodynamic measurements were performed in the voltage range of ± 2.5 V in 0.9% saline. With cobalt-chromium alloys, the corrosion damages the whole stent surface, and ‘316L’ austenitic stainless steel stents are characterized by pitting corrosion.

Additive-made, ‘316L’ stent-like structures show a weight loss after the fatigue test. This phenomenon is not typical of traditionally manufactured implants. Weight loss could be reduced by electropolishing and heat treatment. The weight loss was caused by the detachment of loosely bound dust particles from the surface. The radial load bearing capacity of additively manufactured stent-like structures is greater than that of laser-cut stents of the same geometry. Additively manufactured stent-like structures lose their radial load bearing capacity due to fatigue.

Expected impact and further research

In addition to health engineers, my research results provide important information especially for doctors, because it is difficult to get the results of real comparative measurements to clinical specialists beyond sound marketing materials. My results help physicians provide effective treatment to patients. The research work takes place not only with domestic but also with foreign partners, so the results we have achieved will be outstanding not only in Hungary, but also internationally. In future research, in addition to examining the applicability of new types of manufacturing technologies, research into degradable metallic devices may also be promising. As vascular stenosis remains one of the leading causes of death due to the unhealthy lifestyle of the population (regardless of what viruses are currently destroying the Earth), it is hoped that keeping stent research alive at the University of Technology will always be an important and priority area.

Publications, references, links

https://m2.mtmt.hu/gui2/?type=authors&mode=browse&sel=10061328

Asztalos L, Horicsányi K: Examination of Coatings of Drug-Eluting Coronary Stents. Acta Materialia Transylvanica 2 (2019) pp. 73–78

Károly D, Asztalos L, Fazakas É: Corrosion test of overlapping coronary artery stents made of different materials. Materials Today: Proceedings 5/13 (2018) pp. 26648–26653.

Horicsányi K, Asztalos L, Károly D, Fazakas É: Effect of expansion pressure on the drug eluting coating and the corrosion characteristics of coronary stents; Acta Materialia Transylvanica 1/1. (2018) pp. 37–40.

Károly D, Asztalos L, Micsík T, Szabó P J: Non-Destructive Analysis of Explanted Coronary Artery Stents. Acta Polytechnica Hungarica, 14 (2017) 171–181.

Asztalos L, Schultheiss U, Lulla P, Noster U: Effect of heat and surface treatment on weight loss and fatigue crack initiation of additively manufactured stent-like structures. 11th European Symposium on Vascular Biomaterials. Strasbourg, France 17–19 October 2019 (poster, short oral, abstract)

Asztalos L, Asserghine A, Nagy G, Dobránszky J: A bevonat hatása különböző alapanyagú sztentek korróziós tulajdonságaira. XII. Országos Anyagtudományi Konferencia. Balatonkenese, Hungary, 13-15 October 2019 (poster, short oral, abstract)

Asztalos L, Dobránszky J: Hatóanyag kibocsátó sztentek bevonatának vizsgálata. Tavaszi Szél Konferencia 2019 abstract vol. (Ed. Katalin Németh) p. 450. Debrecen, Hungary, 3–5 May 2019

Asztalos L, Dobránszky J: Hatóanyag kibocsátó sztentek bevonatának vizsgálata. XXIV. Fiatal Műszakiak Tudományos Ülésszaka, Cluj, Romania, 28–29.03.2019 (Presentation)

Horicsányi K, Asztalos L: Sztentbevonatok károsodása in vitro környezetben; IX. Anyagvizsgálat a gyakorlatban konferencia. Székesfehérvár, Hungary, 06–08.06.2018 (Poster)