|

|

BMe Research Grant |

|

Pál Vásárhelyi Doctoral School of Civil Engineering and Earth Sciences

Department of Construction Materials and Technologies / Faculty of Civil Engineering

Supervisor: Dr. Nehme Salem Georges

Influence of additives on the porosity related properties of self-compacting concrete

Introducing the research area

Due to climate change, environmentally-friendly concretes have earned a great attention for the last decades, in terms of research and development. Since concrete is considered an exhaustive material, requiring fossil fuel for its production, the cement industry had been carrying out a lot of studies to reduce the carbon footprint by creating blended cement with additives [1]. Therefore, the application of sustainable concrete with low Portland cement clinker content brings a lot of attention to the construction industry.

Brief introduction of the research place

My research work has been carried out at the accredited laboratory of the Department of Construction Materials and Technologies. The Department is well known for its consultancy, design and inspection work. My supervisor, Salem Georges Nehme is an associate Professor and the Head of the laboratory with a distinct experience in materials engineering and concrete technology.

History and context of the research

The concept of self-compacting concrete was being first applied in Japan in the mid-1980s. Self-compacting concrete is considered as the “most revolutionary development in concrete construction for several decades” [2, A1]. Several advantages characterize self-compacting concrete over normally-vibrated concrete, such as the enhanced workability, safety, ideality for congested reinforcement and others. However, one of the most important concerns regarding self-compacting concrete is the high cost of production due to the implementation of high content of binders which are considered unsustainable if they are used in a high amount. According to Nehdi et al. [3], the cost of materials required for the production of self-compacting concrete is approximately 20-50 % higher than those for normally-vibrated concrete. Therefore, the most effective way to achieve a low cost and sustainable self-compacting concrete is by the utilization of high content of additives as a partial replacement of the Portland cement [4]. These additives could be cementitious, waste or by-product materials which are considered as a part of the powder content utilized in the self-compacting concrete.

The research goals, open questions

The overall aim of the present study was to analyze the effect of using different types of additives on the fresh and hardened properties of sustainable self-compacting concrete. Hungary is one of the most well-known perlite-producing countries worldwide [5]. The physical and chemical characteristics of perlite facilitate its application in construction, horticulture, and other. A local study reported that during the grinding of raw perlite, a huge amount of waste perlite powder is collected and stored as fine-grained waste [6]. The researchers questioned if such waste could be used as a filler material for self-compacting concrete production being the particle-size distribution appropriate.

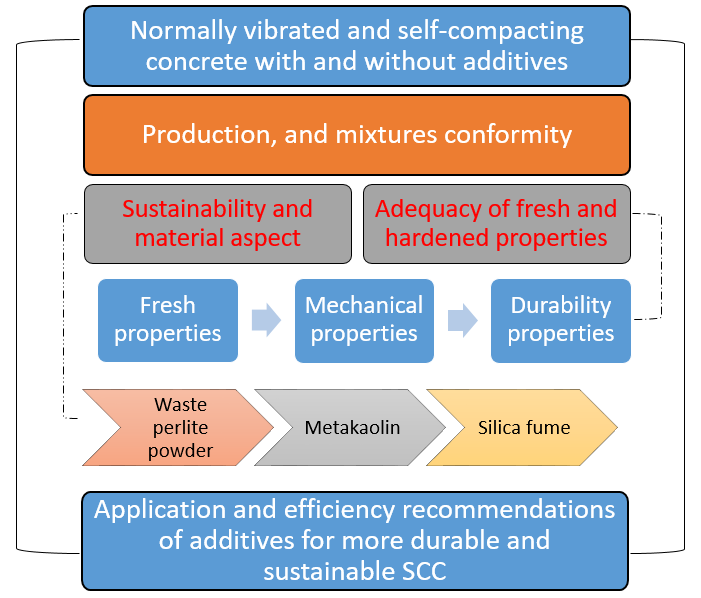

A sustainable self-compacting concrete product could be attained by minimizing the concrete impact on the environment and maximizing its performance. To do so, the utilization of additives at a high content along with the cement binder could serve to the creation of an environmentally-friendly self-compacting concrete. In this study, waste perlite powder, metakaolin and silica fume were the additives which were evaluated for their adequacy and efficiency. Therefore, several laboratory experiments were carried out on produced concretes, with different types of additives and all properties which are directly interconnected to the concretes macro/microstructure were determined (Fig. 1).

Fig.1. Schematic diagram – overall summary of the research work and activities.

By specifying the constrain and variable parameters, the main objectives of this work were the following:

To specify the limits in the workability window of the self-compacting concrete (slump flow diameter vs. v-funnel time) and define the minimum dosage of high range water reducing admixture, in terms of the volumetric water-to-powder ratio.

To evaluate the efficiency of different types of additives for a sustainable self-compacting concrete: fillers (limestone and waste perlite powder) and supplementary cementitious materials (metakaolin and silica fume).

To evaluate the possible effects of alternating the concrete parameters (water-to-binder ratio, water-to-powder ratio, concrete type, admixture type, addition of supplementary cementitious materials, porosity and carbonation) on the repeatability (coefficient of variation) of the rebound surface hardness of the Schmidt hammer.

Methods

In order to achieve the specified objectives, three main experimental programs were selected and aimed to be fulfilled.

The first objective aimed to evaluate the fresh concrete performance to determine the possible changes in the workability window of the self-compacting concrete mixtures (stagnation and segregation phenomena). After mixing the concrete components, properties of the designed fresh self-compacting concretes were evaluated using the slump flow diameter and V-funnel time tests.

On the other hand, ultrasonic pulse velocity, compressive strength, water penetration depth under pressure, total porosity, water absorption by immersion, rapid chloride migration, frost scaling resistance and air void analysis tests were carried out to evaluate the efficiency of different types of additives. Thus, the adequacy of the sustainable self-compacting concrete in terms of mechanical and durability properties could be verified.

Surface hardness, compressive strength, carbonation depth, total and apparent porosity tests were carried out to evaluate the repeatability of the rebound surface hardness of the Schmidt hammer with alteration of the concrete parameters.

Results

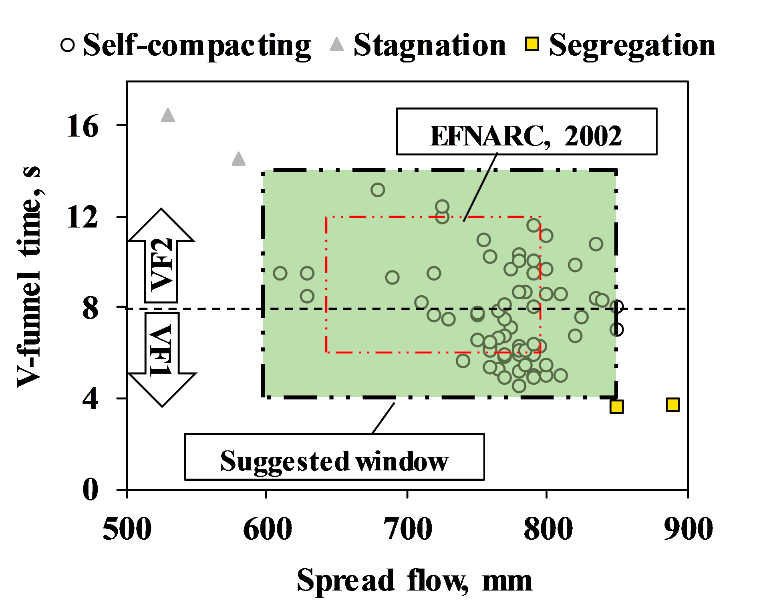

I investigated the fresh properties of 72 self-compacting concrete mixtures using the slump flow diameter and V-funnel time tests to assess the effect of different types of fillers and supplementary cementitious materials, consequently, a comparative evaluation between mixtures was completed. I experimentally developed an extension of the processing window for the self-compacting concrete (Fig. 2) and specified the minimum high range water reducing admixture dosage, in terms of the volumetric water-to-powder ratio [A2, A3].

Fig. 2. Suggested processing window for the self-compacting concrete mixtures, in terms of V-funnel time vs. the slump flow. Viscosity classes (VF1, VF2) corresponds to EFNARC limitations [2]. The red window corresponds to EFNARC limitations [7].

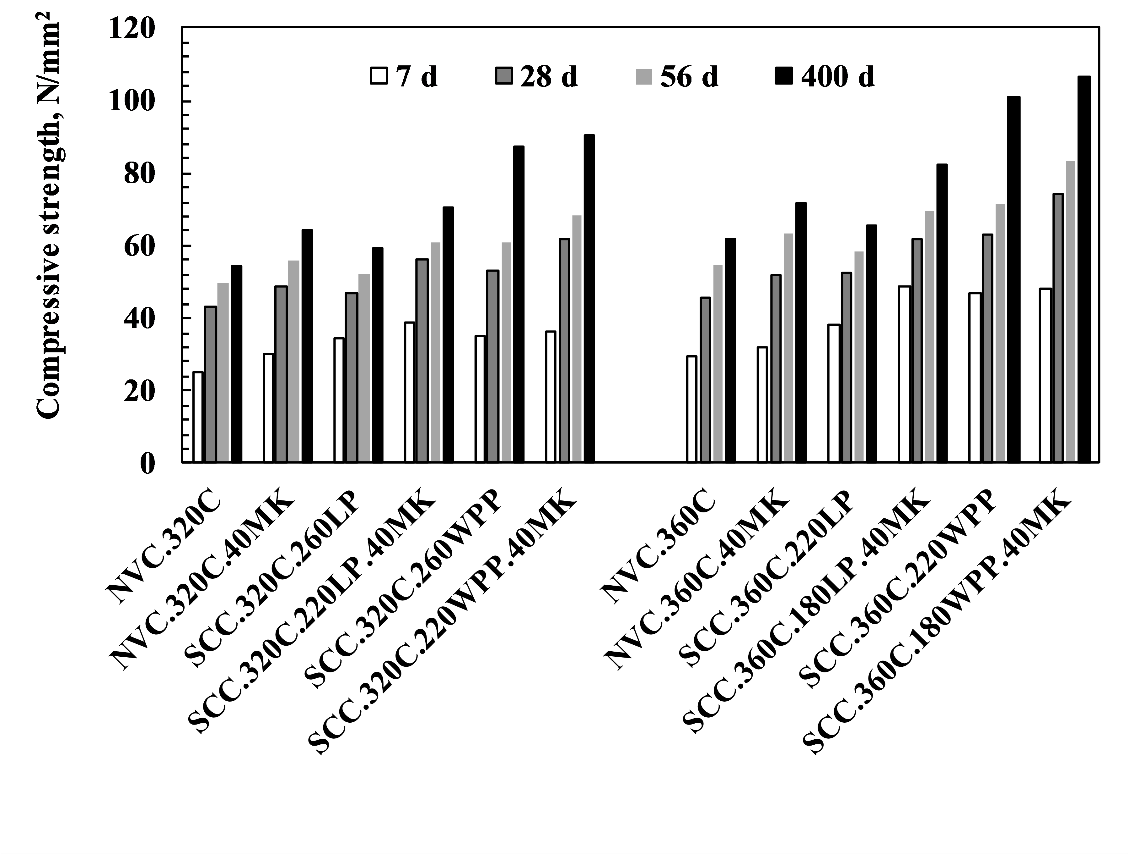

I experimentally demonstrated from the analysis of 2 types of filler (limestone and waste perlite powders) that the use of waste perlite powder in the self-compacting concrete satisfied the workability requirements and was more effective than limestone powder on the compressive strength property (Fig. 3) [A4].

Fig. 3. Mean compressive strength at 7, 28, 56 and 400 days for the normally vibrated (NVC) and the self-compacting concretes (SCC) made with different contents of cement (C: 320, 360 kg/m3), limestone powder (LP: 260, 220, 180 kg/m3), waste perlite powder (LP: 260, 220, 180 kg/m3) and metakaolin (MK: 40 kg/m3).

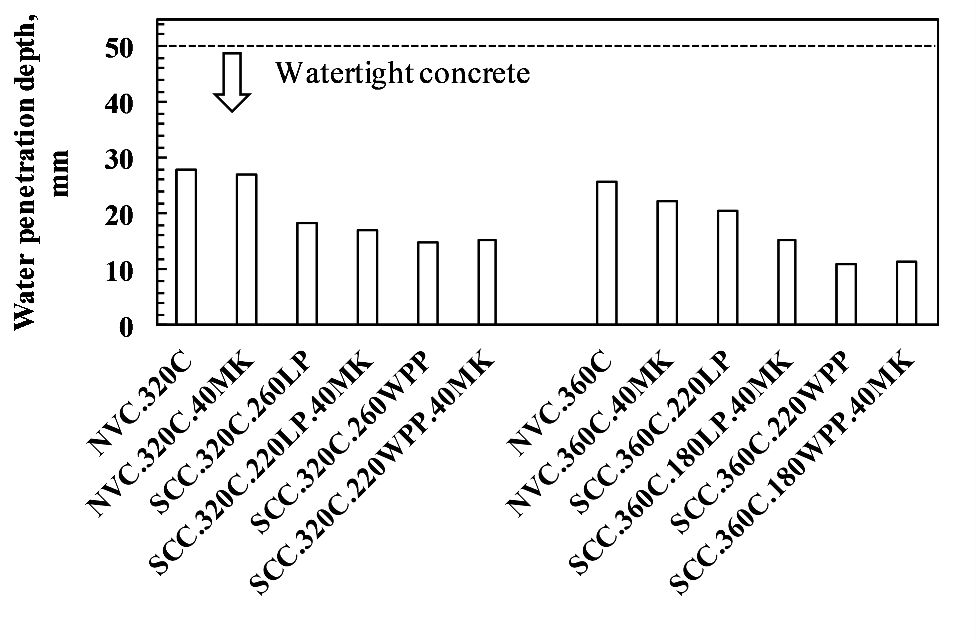

In addition, the waste perlite powder satisfied the durability performance (Fig. 4), in terms of the water penetration depth, water immersion, and rapid chloride migration tests [A4].

Fig. 4. Water penetration depths for the normally vibrated (NVC) and the self-compacting concretes (SCC) made with different contents of cement (C: 320, 360 kg/m3), limestone powder (LP: 260, 220, 180 kg/m3), waste perlite powder (WPP: 260, 220, 180 kg/m3), and addition of supplementary cementitious materials metakaolin (MK: 40 kg/m3).

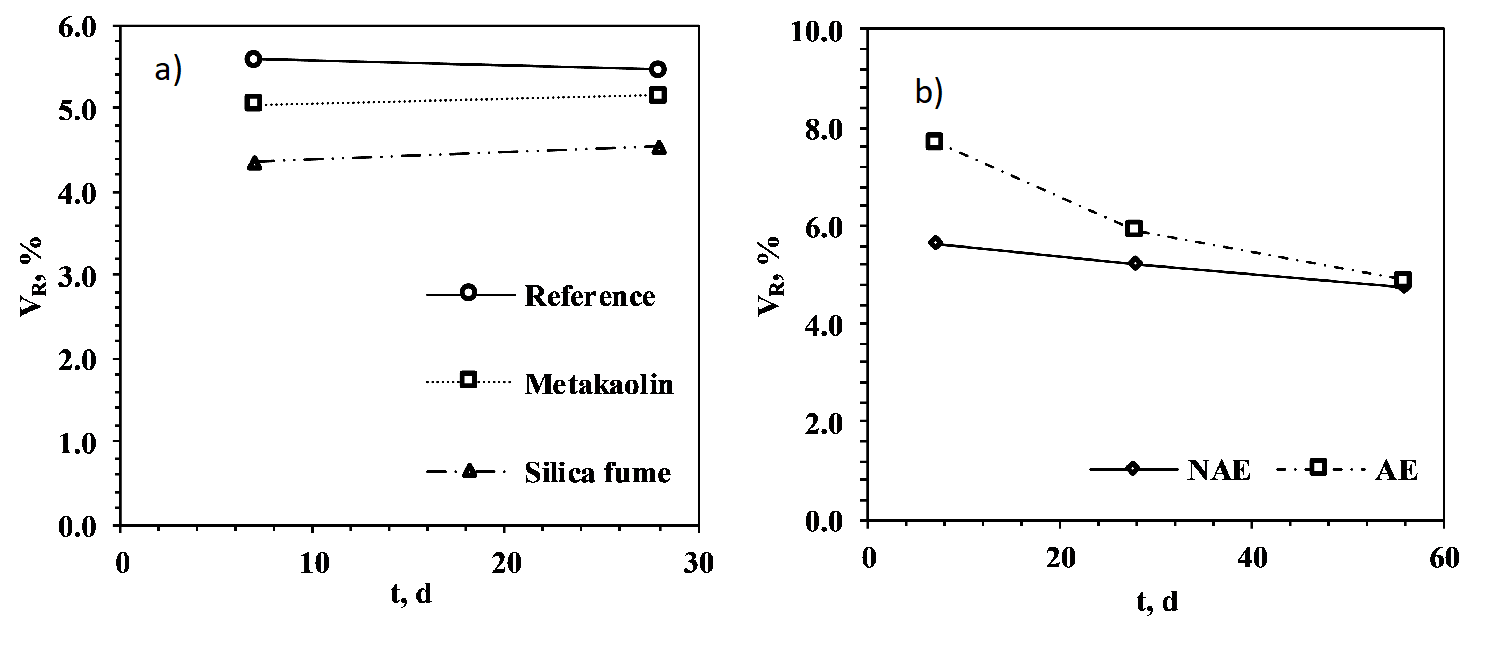

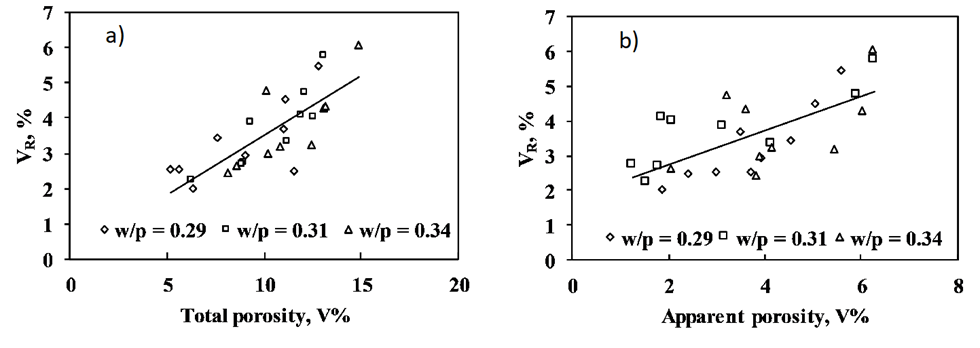

I have experimentally demonstrated from the analysis of 795 specimens in the laboratory (with total number of individual rebound index reading exceeding seven thousand) that the coefficient of variation of the rebound index of the self-compacting concrete is influenced by the water-to-binder ratio, the water-to-powder ratio, the age of concrete, the addition of supplementary cementitious materials (Fig. 5a), the admixture type (Fig. 5b), the porosity measurements (Fig. 6) and the carbonation depth [A5-A8].

Fig. 5. Effect of supplementary cementitious materials (a) and (b) air entraining admixture (AE) on the coefficient of variation (VR) of the rebound index.

Fig. 6. Coefficient of variation of the rebound index as a function of the mean (a) total and (b) apparent porosity provided by different water-to-powder (w/p) ratios.

Expected impact and further research

This research work addressed a suggestion for an alternative type of filler (waste perlite powder) for the production of a sustainable self-compacting concrete. The results indicated that waste perlite powder had a significant pozzolanic and curing effect on the concrete microstructure, resulting in a positive impact on the hardened properties of concrete. Furthermore, enhanced durability of the self-compacting concrete mixtures incorporating waste perlite powder were obtained.

Along this study, an extensive analysis on several parameters affecting the repeatability of the surface hardness of the Schmidt hammer was performed. As ultra-high strength concrete resulted in very low rebound index coefficient of variation, the predication of ultra-high strength concrete actual compressive strength would be reliable. The next logical step is to investigate structural elements produced with the same materials relevant to our laboratory research. Afterwards, an objective comparison between the in-situ and the laboratory results can be completed to verify such behavior. As a general remark, further research is needed to improve the reliability of the use of the Schmidt hammer since it is considered a cost-effective tool for the compressive strength assessment.

Publications, references, links

Two of my publications [A4, A5] were issued in worldwide recognized journals concerning sustainability and building material (Journal of Cleaner Production / IF: 5.715 and Journal of Construction and Building Materials / IF: 3.169). Other articles were published in peer-reviewed journals and Scopus indexed conferences.

List of corresponding own publications

[A1] El Mir A., Nehme S. and Nehme K. 2016. Latest updates and developments on self-compacting concrete. Report of RILEM symposium 2016. Journal of Silicate Based and Composite Materials, Vol.17, pp. 8–12.

[A2] El Mir A. and Nehme S. 2017. Assessment of the fresh self-compacting concrete properties utilizing different types of additives. Journal of Silicate Based and Composite Materials, Vol.69, pp. 83–88.

[A3] El Mir A. and Nehme S. 2017. Long term mechanical properties of self-compacting concrete made with slag cement and supplementary cementitious materials. Journal of Silicate Based and Composite Materials, Vol.69, pp. 59–65.

[A4] El Mir A. and Nehme S. 2017. Utilization of industrial waste perlite powder in self-compacting concrete. Journal of Cleaner Production, Vol.156, pp. 507–517.

[A5] El Mir A. and Nehme S. 2016. Repeatability of the rebound surface hardness of concrete with alteration of concrete parameters. Construction and Building Materials, Vol.131, pp. 317–326.

[A6] El Mir A. and Nehme S. 2015. Porosity of self-compacting concrete. Procedia Engineering, Vol.123, pp. 145–152.

[A7] El Mir A. and Nehme S. 2015. Accelerated carbonation effect on the rebound index of SCC. 11th Central European Congress in Concrete Engineering, Hainburg, Austria.

[A8] El Mir A. and Nehme S. 2015. Application of non-destructive test on self-compacting concrete. IABSE Conference - Structural Engineering: Providing Solutions to Global Challenges, Geneva, Switzerland.

List of references

[1] Mikulčić H., Klemes J., J., Vujanovic M., Urbaniec K. and Duic N. 2016. Reducing Greenhouse Gasses Emissions by Fostering the Deployment of Alternative Raw Materials and Energy Sources in the Cleaner Cement Manufacturing Process. Journal of Cleaner Production, Vol.136, pp. 119–32.

[2] EFNARC. 2005. The European Guidelines for Self-Compacting Concrete. European Guideline for Self Compacting Concrete.

[3] Nehdi M., Pardhan M., and Koshowski S. 2004. Durability of Self-Consolidating Concrete Incorporating High-Volume Replacement Composite Cements. Cement and Concrete Research, Vol.34, pp. 2103–2112.

[4] Dinakar P., Kartik M. and Mudit S. 2013. Behaviour of Self Compacting Concrete Using Portland Pozzolana Cement with Different Levels of Fly Ash. Materials and Design, Vol. 46, pp 609–16

[5] U.S. Geological Survey. 2016. Mineral Commodity Summaries 2016. U.S. Geological Survey Reston.

[6] Farkas G., Mucsi G., Szabó R. and Kristály F. 2015. The characteristics of fine fractions of perlite. Journal of Mining and Metallurgy Sheets, Vol. 6, 22–26 (in Hungarian).

[7] EFNARC. 2002. Specification and Guidelines for Self-Compacting Concrete. European Guideline for Self Compacting Concrete.