|

|

BMe Research Grant |

|

Géza Pattantyús-Ábrahám Doctoral School of Mechanical Engineering

Department of Polymer Engineering/ Budapest University of Technology and Economics

Supervisor: Dr. József Gábor Kovács

High performance thermally conductive and electrically insulation polymer composites for electronic devices

Introducing the research area

To ensure efficient dissipation of the heat generated by electric and industrial devices is a difficult task for the engineers. Efficient heat dissipation is inevitable for secure and long term operation of the devices [1-3].

The goal of my research is to develop high performance thermally conductive polymer composites which can replace the conventionally used metal heat sinks in certain areas. These polymer based materials have many advantages over the metals, such as the low density, low production cost, good corrosion resistance, fast and well-automated processing technologies and the omission of post-processes. Hence, these special materials have potential in the cooling of electric and mechatronic parts. Conventionally, the cooling of mechatronic parts is solved by extruded or casted metal heat sinks. To guarantee the electronic insulation between the electric circuit and the heat sink, conductive plastic film is applied as a barrier. However, these polymer films make the assembly process complicated and decrease the efficiency of heat transport. Thus the effectiveness of the metal heat sink also decreases [1]. Accordingly, eliminating the polymer barrier can result in thermally conductive and electrically insulating polymer composites, innovative materials for future device development.

Brief introduction of the research place

The research work was carried out at BUTE, Department of Polymer Engineering. The department focuses on the development of polymer based structural material. Among the Hungarian universities, this department introduced first the ISO 9001 quality management system and the laboratory is accredited by the Hungarian Accreditation Board. The high level scientific activity of the department is marked by its own issued international journal, the Express Polymer Letters.

History and context of the research

In the last decades in engineering practice there is a great demand for polymer based structural materials to replace metallic parts. Until recently, research was targeted at improving the mechanical properties of polymers to attain the strength of the steel. These developments were based on the application of fiber-like reinforcements. On the other hand, additionally to the mechanical properties, metals also outperform polymers in thermal characteristics. In several applications, there is a huge demand for electrically insulator materials with good thermal conductivity. Majority of demands for these materials come from electronics, where heat dissipation is a key issue to extend the lifespan of devices, and at the same time keeping the electrical insulating behavior is required to eliminate the short circuit failures and other errors [4, 5]. A possible new solution for this problem can be thermally conductive polymer composites. The initial stage of introducing these innovative materials was triggered by the fast development of the LED (Light-Emitting-Diode) technology.

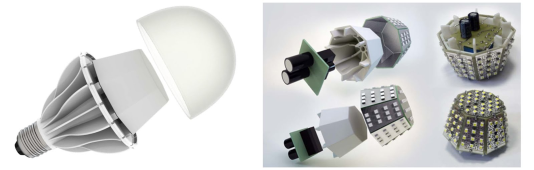

The designed LED bulb with thermally conductive polymer parts

While the conventionally used light sources (conventional incandescent, fluorescent, high intensity discharge) emit 90% of generated heat toward the environment, LEDs dissipate this amount of heat to the printed circuit boards [6]. As these boards have low thermal conductivity, heat dissipation is inefficient. Therefore, even a small increment in operating temperatures (about 10–15°C) can halve the lifespan of the devices [4]. In the electronic packaging, thermally conductive polymers are novelties but increasingly more engineers consider them an alternative solution.

The research goal, open questions

The main goal of my research is to develop new polymer based composite materials with high thermal conductivity. A further important aspect of the composite is to maintain electrical insulation behavior so that it can be directly used as electronic packaging, without additional thermal barrier material. Also, extending the area of application of these materials allow us to replace the conventionally used ceramic and metal cooling units with the less costly polymer composites. Furthermore, the modeling and prediction of the thermal conductivity of these special materials is important to tailor the properties to match actual needs.

This research involves solving of multiple problems. One of them is that the highly filled polymer composites should be processed with the conventionally used industrial processing machines (injection molding machine, extruder and so on). A further important task is to reveal the thermal and mechanical properties of composites and their dependency on the filler properties. Furthermore, a knowledge on the exact properties of raw materials is also required to provide more precise parameters for the mathematical model development. To answer the emerging questions, beyond the conventional mechanical, thermal and morphological investigations, self developed measurement devices and measurement methods must also be applied.

Methods

Materials

As composite matrix materials, polypropylene, polyamide 6 and polylactic acid were used. Using the common polymer Polypropylene is cost efficient, polyamide 6 is a good engineering material and the polylactic acid is a biodegradable polymer from renewable resources. As conductive fillers talc, boron nitride and graphite were used. Due to the plate-like shape (flake) of these fillers, their properties show anisotropy. The diameter of single plates is 5-50 microns, and their thickness is in the nanometer range. While talc is a cost efficient, low conductivity material, graphite and boron nitride are the best thermally conductive fillers.

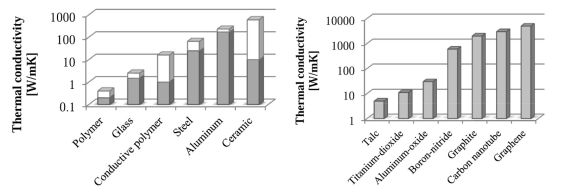

Thermal conductivity of common materials and fillers

Preparation of samples

The composites were prepared by twin screw extruder and internal mixer. To demonstrate the effects of the different processing methods, the samples were produced with injection molding and hot pressing. For the investigation of the effectiveness of surface treatment, the boron nitride particles were surface treated with silane.

Measurement methods

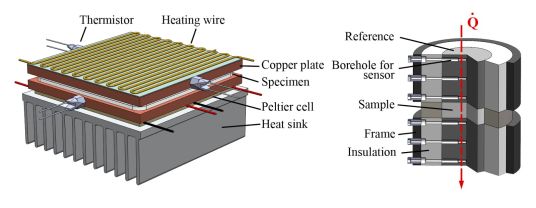

The thermal conductivity of the composites was determined with two different methods. The first is the so called Hot-Plate method [7]. The aim of the measurement is to generate heat difference (about 10°C) between the two sides of the analyzed flat specimen, so the heat flows through the specimen from the hot side toward the cold one. After reaching the steady state condition, thermal conductivity can be calculated according to Fourier’s law. The other measurement process is called Linear-Heat flow method [8]. During the measurements, the temperature gradient of the specimen is compared to the temperature gradient of the reference sample. Thermal conductivity can be also calculated from Fourier’s law.

Furthermore, the effect of fillers on the quasistatic and dynamic mechanical properties and thermal properties of the composites were also analyzed through tensile tests, three-point bending tests, Charpy tests and DSC, DMA analysis.

Modeling

Additionally to the mechanical properties, thermal conductivity of polymer composites also have to be designed according to the particular needs. Therefore, a semi-empirical mathematical model was developed, which was based on the rule of mixtures. To determine the main material properties for the model, a measurement methodology was also developed.

Results

Development of measurement systems

To determine the exact thermal conductivity of the materials (raw materials and composites), two different conductivity measurement systems were built, calibrated and tested. The hot pressed and injection molded specimens were tested on the Hot-Plate apparatus and the hot pressed cylindrical samples and the fillers were tested with the Linear-Heat flow system.

The developed Hot-Plate and Linear-Heat flow thermal conductometers

Main parameters influencing thermal conductivity

The first experiments wanted to explore the main parameters that have significant influence on the thermal conductivity of the composites. These main parameters are the filler content, filler type, the type of matrix material and the processing methods. It was concluded that the filler type and filler content have the highest influence on thermal conductivity. Applying different matrices modified these results only by 0.1-0.3 W/mK.

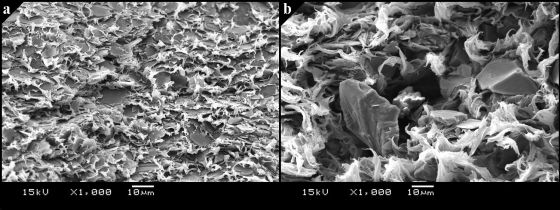

It was also revealed that the processing method as well has a great influence on the results. The main reason is that during the injection molding process, fillers migrate from the shell of the molded part toward the core. Furthermore, residual anisotropic fillers in the shell are oriented toward the flow direction. This effect should be also considered during the product design and when designing the melt flow direction.

Scanning Electron Microscopic picture of polypropylene based thermally conductive composites with boron nitride (a) and talc (b) fillers

Material development

The most important and most efficient processing method in the plastic industry is injection molding. However, this processing method limits the filler content in polymers due to the increase in viscosity. Consequently, thermal conductivity range is also limited. To increase the thermal conductivity limited by the processing method, multiple solutions were developed. The first solution is based on the use of hybrid fillers, where the synergetic effect increases thermal conductivity. As a goal of my work, a hybrid filler system was developed using talc and boron nitride. With proper mixture of components, the thermal conductivity achieved exceeded the value forecast by the rule of mixtures. The second solution is the surface treatment of the particles. Various silane based surface treatment methods were developed for boron nitride where 5-30% increase in thermal conductivity could be observed at decreasing viscosity. The third solution targets the decrease the viscosity of matrices. Viscosity measurements proved that using 1-2% cyclic butylene terephthalate monomer, flowability of the composites can be improved significantly, meanwhile it has no effect on the mechanical properties. It can extend the filler content limit in the processing methods, and thus the achievable thermal conductivity, too.

Modeling

During my work, multiple theoretical models for thermal conductivity prediction was investigated, and manifested its weaknesses and limits. The conclusion was that a non-linear relation exists between thermal conductivity and filler content. Also, a semi-empirical mathematical model was developed from the rule of mixtures. To evaluate the model, different plate shaped fillers of significantly different thermal conductivity was used. The new model was found to predict the thermal conductivity of composites more precisely than the conventionally used theoretical models. To determine the input parameters of the model, self developed measurement systems were used and new methodologies were developed.

Expected impact and further research

In my work, varied thermally conductive mono and hybrid composites were developed. These special materials can be applied in certain industrial applications, like in cooling units. These composites can be processed economically with conventional plastic processing equipment without damaging them. The developed mathematical model and measurement methods are suitable for precise tailoring the thermal conductivity of polymer composites.

In the future, I would like to develop hybrid composites that contain conductive fillers and short or long fibers. These kinds of materials not only suitable for heat emission from the devices but also for building structural parts. With this step, the application area of conductive polymers can be significantly extended.

Publications, references, link collection

Related own publications:

[P1.] J. G. Kovács, G. Körtélyesi, N. K. Kovács, A. Suplicz: Evaluation of measured and calculated thermal parameters of a photopolymer. International Communication in Heat and Mass Transfer, 38, 863-867 (2011). (IF=1.892)

[P2.] Kovács N K, Suplicz A, Kovács J G: Gyors prototípusgyártás, mint újszerű fröccsöntő szerszámozási technológia (in Hungarian). Műanyagipari Évkönyv, 9, 45-53 (2011).

[P3.] A. Suplicz, J. G. Kovács: Development of thermally conductive polymer materials and their investigation. Material Science Forum, 729, 80-84 (2013).

[P4.] J. G. Kovács, A. Suplicz: Thermally Conductive Polymer Compounds for Injection Moulding: The Synergetic Effect of Hexagonal Boron Nitride and Talc. Journal of Reinforced Plastics and Composites, 32, 1234-1240 (2013). (IF=0.902)

[P5.] Suplicz A, Szabó F., Kovács J G: Anyagvizsgálati módszerek fejlesztése fröccsöntési alkalmazáshoz (in Hungarian). Műanyagipari Évkönyv, 11, 34-41 (2013).

[P6.] A. Suplicz, F. Szabo, J. G. Kovacs: Injection molding of ceramic filled polypropylene: The effect of thermal conductivity and cooling rate on crystallinity. Thermochimica Acta. 574, 145-150 (2013). (IF=1.989)

[P7.] Suplicz A., Kovács J. G.: Hővezető polimerek az elektrotechnikában – hibrid rendszerű töltőanyagok alkalmazásának előnyei (in Hungarian). Műanyag és Gumi, 4, 156-160 (2014).

[P8.] L. Zsíros, A. Suplicz, G. Romhány, T. Tábi, J.G. Kovács: Development of a novel color inhomogeneity test method for injection molded parts. Polymer Testing, 37, 112-116 (2014). (IF=1.646)

[P9.] T. Tábi, A. Suplicz, T. Czigány, J. G. Kovács: Thermal and mechanical analysis of injection moulded Poly(Lactic Acid) filled with Poly(Ethylene Glycol) and talc. Journal of Thermal Analysis and Calorimetry (under revision) (IF=1.982)

[P10.] A. Suplicz, J. G. Kovacs: Analysing the thermal properties of the PolyJet photopolymer. Gépészet 2010: Proceedings of the Seventh Conference on Mechanical Engineering. Budapest, Hungary, 05.25.2010-.05.26.2010. Budapest: Budapest University of Technology and Economics, pp. 153-159. (ISBN: 978-963-313-007-0).

[P11.] A. Suplicz, J. G. Kovacs: Development of thermal conductive hybrid composites. Proceedings of the 15th European Conference on Composite Materials (ECCM15). Venice, Italy, 06.24.2012-06.28.2012 pp. 1-6. Paper 1562. ISBN: 978-88-88785-33-2.

[P12.] Suplicz A., Szabó F., Kovács J. G.: Hővezető polimerek fejlesztési lehetőségei és vizsgálati módszerei (Development possibilities and analyzing methods of thermally conductive polymers). Nemzetközi Gépészeti Találkozó – (OGÉT), Arad, Romania, 04.25-28, 2013, pp. 346-349. ISSN: 2068-1267

[P13.] Szabó F., Suplicz A., Kovács J. G.: Anyagtulajdonságok újszerű mérési lehetőségei (Novel methods for material properties measurements). Nemzetközi Gépészeti Találkozó – (OGÉT), Arad, Romania, 04.25-28, 2013, pp. 350-353. ISSN: 2068-1267.

[P14.] J. G. Kovacs, A. Suplicz: Improved thermal properties with hybridization of the fillers for thermoplastic materials. Proceedings of the 19th International Conference on Composite Materials. Montreal, Canada, 07.28.2013-08.02.2013, ICCM, pp: 4011-4018. ISBN:978-0-9696797-1-4.

References:

[1] Amesöder S., Heinle C., Ehrenstein G.W., Schmachtenberg E.: Injection moulding of thermally conducting polymers for mechatronic applications. The Polymer Processing Society 23rd Annual Meeting, Salvador, Brasil (2007).

[2] Han Z., Fina A., Thermal conductivity of carbonnanotubes and their polymer nanocomposites: A review. Progress in Polymer Science 36, 914-944 (2011).

[3] Zhou T., Wang X., Cheng P., Wang T., Xiong D., Wang X.: Improving the thermal conductivity of epoxy resin by the addition of a mixture of graphite nanoplatelets and silicon carbide microparticles. eXPRESS Polymer Letters 7, 585-594 (2013).

[4] Zhou W, Qi S, An Q, Zhao H, Liu N. Thermal conductivity of boron nitride reinforced polyethylene composites. Material Research Bulletin, 42, 1863-1873 (2007).

[5] Gu J, Zhang Q, Dang J, Zhang J, YangZ. Thermal Conductivity and Mechanical Properties of Aluminum Nitride Filled Linear Low-Density Polyethylene Composites. Polymer Engineering and Science, 49, 1030-1034 (2009).

[6] Petroski J.: Thermal Challenges In LED Cooling. Electronics Cooling. 01.11.2006.

[7] Maglic K. D., Cezairliyan A., Peletsky V. E.: Compendium of Thermophysical Property Measurement Methods. Plenum Press, New York, 1984.

[8] Azeem S., Zain-ul-Abdein M.: Investigation of thermal conductivity enhancement in bakelite-graphite particulate filled polymeric composite. International Journal of Engineering Science, 52, 30-40 (2012).