|

|

BMe Research Grant |

|

Géza Pattantyús-Ábrahám Doctoral School of Mechanical Engineering

Faculty of Mechanical Engineering/Department of Materials Science and Technology

Supervisor: László Dévényi Ph.D.

Microstructural and mechanical anomalies in mild steels

Introducing the research area

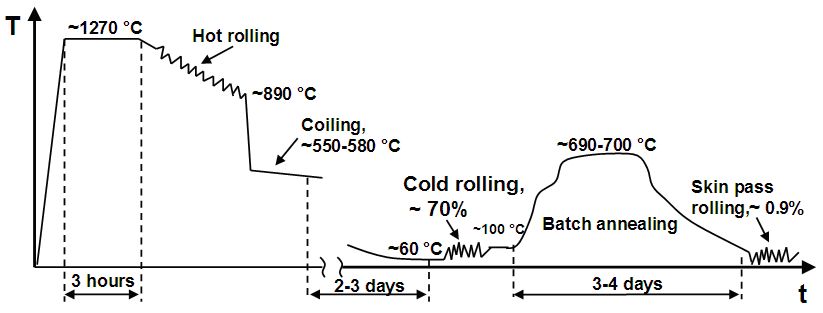

The research includes the metallurgical background of production method of aluminium killed low carbon steels as well as the explanation of several very rare anomaly. The first task to complete was the optimisation of production technology of DC04-05 cold forming sheets produced by ISD Dunaferr. The optimisation results in the modification of several technological parameters including the introduction of a new heat treatment methodology [S1]. ISD Dunaferr produces its DC04-05 sheets according to this optimised technology since 2012 [S2]. The time (t) - temperature (T) function of the optimised production technology is shown in Fig. 1.

Fig.1. The optimised production technology of DC04-05 sheets and its parameters

The key element of production technology is the proper treatment of nitrogen-containing compounds: keeping nitrogen in solid solution until the beginning of the annealing treatment, and inducing nitride precipitation during the heating up stage of the annealing treatment before the recrystallisation between 400 and 550 °C [1] , [2].

Brief introduction of the research place

The measurements were performed in the Department of Materials Science and Technology at Budapest University of Technology and Economics and in the laboratories of Dunaferr Innovation Center. Prosperous international cooperation has been evolved with the co-workers of Csinghua University, Beijing and Niobelcon BVBA.

History and context of the research

The difficulties in the measurement of nitride precipitation processes are caused by the low quantity of nitrogen: usually 0.005-0.006 w.t % is (may be) present in these type of steels.

There are several methods for measuring nitride precipitation processes; however, the measurement of such small quantities is not easy [3], [4]. The only solution is the measurement of the thermoelectric coefficient (Seebeck coefficient) of the steel. Only the ultra low noise DC amplifiers developed in the last decade opened the door to the development of sensitive and high-resolution thermoelectric power measuring devices. Using these devices, nitride precipitation process has been already investigated in hot rolled steels [4]; however, there were no methods to measure the process in cold rolled sheets before my related results were published.

The research goal, open questions

My literature survey revealed that the evaluation of the degree of nitride precipitation in cold rolled sheets was not yet sold. Solving this problem had become the first aim of my researches [S3], [S6], [S7].

Another open question, the effect of hot rolled grain size on the precipitation of nitrides on hot and cold rolled states had become the second target of my research. [S3].

Literature results suggested that the upper yield strength measured after heat treatment is extremely sensitive to the test circumstances (the gripping system applied). The clarification of this question needed further researches as well, and it was the third realised aim of my research [S4], [S5].

Methods

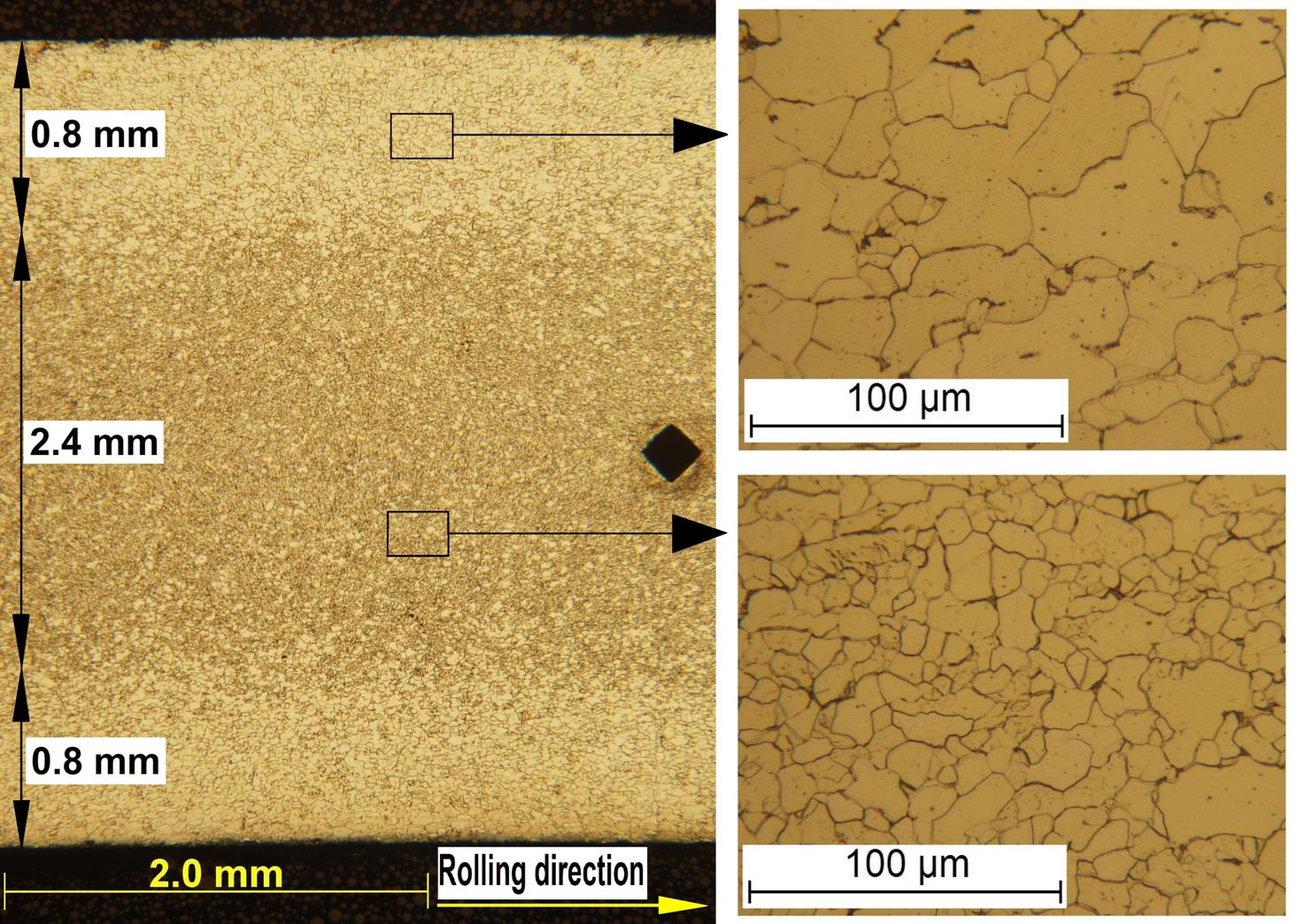

The effect of hot rolled grain size on the precipitation kinetics of nitrides was studied on a very rare microstructure exhibiting layered grain size distribution (Fig. 2)

Fig. 2. Special, layered grain size microstructure in hot rolled sheet [S3]

The average grain size differs markedly in the layers: the average grain size was 23 μm and 9 μm in the border and centre regions, respectively. Specimens were prepared from the border and centre regions of the sheet, on which the effect of grain size on the precipitation kinetics was investigated. In order to investigate the nitride precipitation kinetic, thermoelectric power measurements were performed. The thermoelectric power of a specimen is measured by fixing it between two large heat capacity copper block having different temperature, leading to a electric potential difference. The electric voltage measured between the copper blocks is related to the microstructural state of the specimen. The nitride precipitation process was investigated in both cold and hot rolled state.

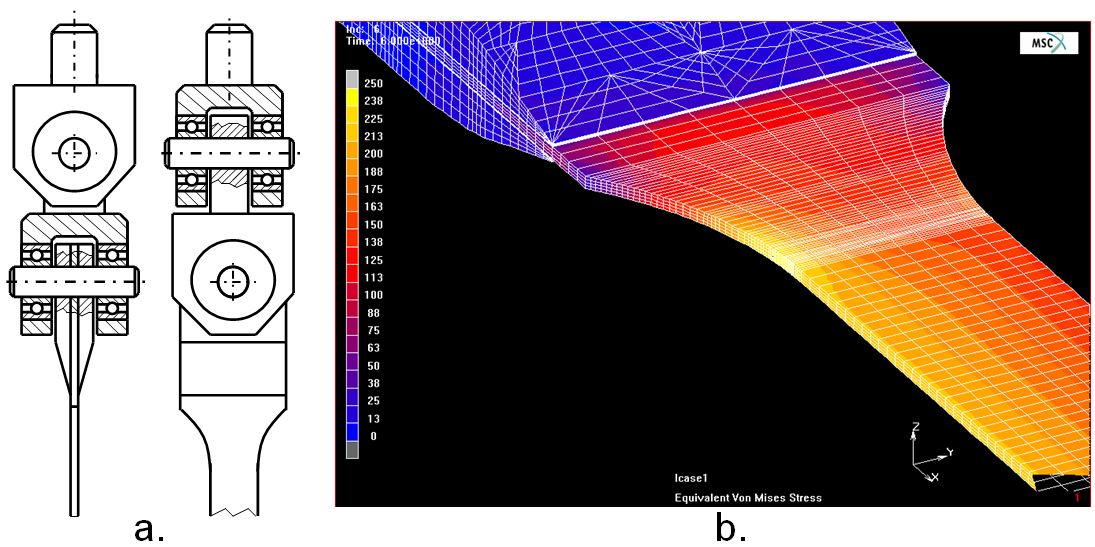

During the measurement of upper yield strength in heat treated state, the critical point is the eccentricity between the loading and axis of symmetry of the test piece. [5-8]. In order to adjust the eccentricity error and investigate its effect on upper yield strength, a novel gripping system has been developed. [S4], [S5] , [S8] (Fig.3).

Fig. 3. Self-designed gripping system for exact measurement of upper yield strength [S4] (a.) and the FEM simulation of the stress distribution in a tensile test specimen loaded with 0.5 mm eccentricity [S8] (b.)

Results

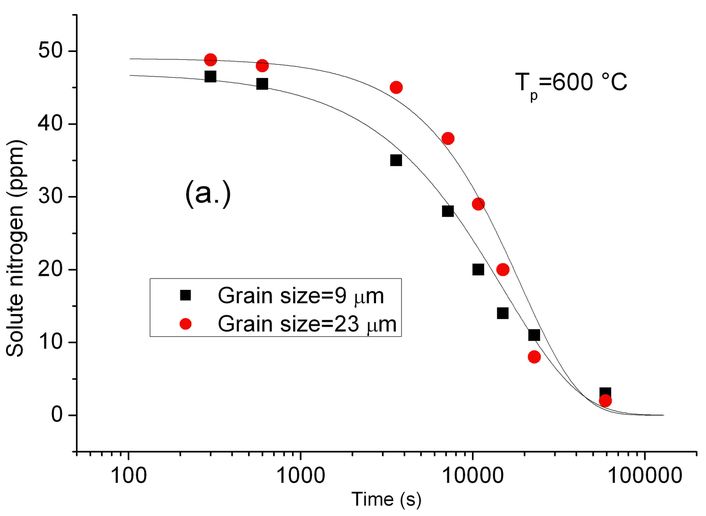

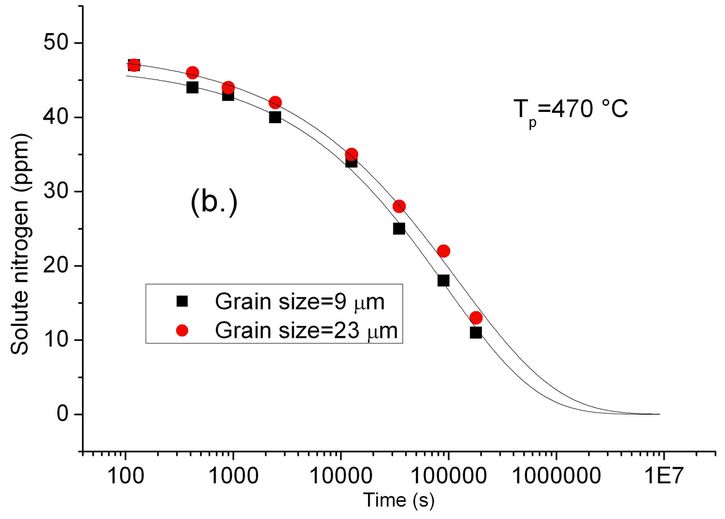

The nitride precipitation kinetics has been investigated in hot rolled state in the temperature interval 550...700 °C, whilst in cold rolled state, the precipitation kinetics has been evaluated between 430 and 510 °C. Figure 4 shows two examples for precipitation kinetics at 600 and 470 °C [S3].

Fig. 4. Nitride precipitation process at 600 °C in hot rolled state and at 470 °C in cold rolled state [S3]

To optimize industrial annealing heat treatment nitride precipitation kinetics was used. The heat treatment is performed in a bell-type batch annealing furnace. In furnace, 3-4 cold rolled coils are placed on each other vertically, and they are heated externally using a bell shape heat transferring cover. Heat convection between the bell and the coils is assured by the inert gas atmosphere of the furnace. Finite element simulation of the heat treatment was used for the estimation of the temperature distribution and the optimal heat cycle for annealing.

Fig. 5. The assembly of a batch annealing furnace [9] and the numerical simulation of heat transport [S1]

Results of finite element simulation and experimental work showed that the nitride precipitation process should reach at least 50 % before the onset of recrystallisation. Based on this condition, a proper heat treatment cycle could be planned that ensured the excellent formability and economical production of DC04-05 sheets. [S1],[S2].

The studies related to the measurement of upper yield strength provided surprising results. Beside a quasi-static loading, the upper yield strength of these steels could exceed tensile strength; moreover, this value can change in a wide range depending of the eccentricity of the loading. The upper yield strength at one DC05 sheet decreased by 16 MPa due to the increase of eccentricity by 0.1 mm [S4].

Expected impact and further research

As a result of my researches, several mathematical models for describing the nitride precipitation in hot and cold rolled DC04-05 steels and its relation to the recrystallisation and to the mechanical properties have been developed. A novel gripping system for the accurate measurement of upper yield strength has also been constructed.

The results of the research have been adopted in the industrial practice by ISD Dunaferr. Main conclusions and results have been published in impact factor journals. The research continues with the implementation of the newly developed models for measuring the solute/bounded boron content of steel.

Publications, links, references

Publications

[S1] Felde I, Mucsi A, Reger M: Simulation of Annealing Process for Cold-Rolled Strip Steel

In: D Scott Mackenzie (Ed.) 6th International Conference on Quenching and Control of Distortion: Including the 4th International Distortion Engineering Conference. Chicago, IL, USA, Sept. 09-13, 2012, Ohio: ASM International, 2012. pp. 839-847. (ISBN:978-1-61503-980-7)

[S2] Mucsi András, Földi József, Kardos Ibolya, Felde Imre, Palkovics Miklós: Hidegen hengerelt szalagok lágyítási műveletének gyártástechnológiai felülvizsgálata, optimalizálása (in Hungarian), ISD DUNAFERR MŰSZAKI GAZDASÁGI KÖZLEMÉNYEK 165, pp. 120-125. (2012)

[S3] András Mucsi: Effect of hot rolled grain size on the precipitation kinetics of nitrides in low carbon Al-killed steel, JOURNAL OF MATERIALS PROCESSING TECHNOLOGY 214:(8) pp.1536-1545. (2014), IF=1.95

[S4] András Mucsi : Effect of gripping system on the measured upper yield strength estimated by tensile tests, MEASUREMENT 46, pp. 1663-1670. (2013), IF=1.13

[S5] András Mucsi: Analysis of Stress Distribution in Tensile Test Specimens Using Modified Versions of a Novel Gripping System, UNIVERSAL JOURNAL OF MECHANICAL ENGINEERING 1:(4) pp. 109-113. (2013)

[S6] András Mucsi, I Felde: Simulation and measurement of aluminium– nitride precipitation in hot rolled Al killed low carbon steel coil, INTERNATIONAL HEAT TREATMENT AND SURFACE ENGINEERING 7:(4) pp. 171-174. (2013)

[S7] András Mucsi: Alumíniummal csillapított acélszalagok nitridkiválási folyamatai a meleghengerlést követő technológiai műveletek során (in Hungarian), BÁNYÁSZATI KOHÁSZATI LAPOK-KOHÁSZAT 146:(5-6) pp. 1-6. (2013)

[S8] Mucsi András, Sárossy György:Hőkezelési és alakváltozási paraméterek összefüggései alumíniummal csillapított lágyacél lemezek esetén (in Hungarian), In: Pálinkás Sándor, Szabó Gábor, Szűcs Máté (Ed.) XIV. Képlékenyalakító konferencia: Feb.16-18, 2012, Miskolc, Hungary, pp. 206-215. (ISBN:978-963-661-985-5)

Links

Measurement of thermoelectric power:

http://www.nist.gov/mml/mmsd/sustainable-materials/thermoelectric-measurement.cfm

Bell-type batch annealing technology:

http://ispatguru.com/annealing-of-cold-rolled-steel/

ISD Dunferr, production technology:

http://www.dunaferr.hu/en/products/technology

References

[1] R. K. Ray, J. J. Jonas, R. E. Hook, Cold rolling and annealing textures in low carbon and extra low carbon steels, INTERNATIONAL MATERIALS REWIEVS 39, pp. 129-172, (1994)

[2] S. S. Satyam, B. J. Kishor, Heating rate effects during non-isothermal annealing of AlK steel, JOURNAL OF MATERIALS ENGINEERING AND PERFORMANCE 12, pp. 157-164, (2003)

[3] F. G. Wilson, T. Gladman, Aluminium Nitride in Steel, INTERNATIONAL MATERIALS REWIEVS 33, pp. 223-286, (1988)

[4] V. Massardier, V. Guétaz, J. Merlin, M. Soler, Kinetic and microstructural study of aluminium nitride precipitation in a low carbon aluminium-killed steel, MATERIALS SCIENCE AND ENGINEERING A 355, pp. 299-310, (2003)

[5] J.R. Davis, Tensile Testing, second ed., ASM International, USA, 2004.

[6] T.G.F. Gray, A. McCombe, Influence of specimen dimension and grip in tensile testing steel to EN 10 002, J. IRON AND STEEL MAKING 19, pp. 405–409, (1992)

[7] Hong-Bing Sun, Yuya Kaneda, Masanobu Ohmori, Fusahito Yoshida, Effect of stress concentration on upper yield point in mild steel, MATER.TRANS. 47, pp. 96-100, (2006)

[8] M.M. Hutchinson, High upper yield point in mild steel, J. IRON AND STEEL INST. 186, pp. 431–432, (1957)

[9] Gárdus Zoltán: Hőkezelő harangkemencék falazatkorszerűsítése (in Hungarian), Ph.D. thesis, Miskolc, July, 2013