|

BMe Research Grant |

|

Doctoral School of Electrical Engineering

Department of Electron Devices

Supervisor: Dr. Székely Vladimír, member of the Hungarian Academy of Sciences

Modeling and Characterization of Microsensors and Actuators

Introduction of the research area

The main element of the modern sensor and actuator systems are the so called micro-(opto)-electromechanical systems (M(O)EMS). These devices are in the micrometer to millimeter range, and utilizing their electromagnetic, optical, chemical, thermal and mechanical properties to generate electric signals for electrical circuits or produce other observable phenomena. During my researches, I’m dealing with the examination of such microsystems. As a result of my investigations, I have developed new characterization techniques and models which could contribute to the optimal design of future microsystems.

Brief introduction of the research place

My research work is carried out at the Department of Electron Devices, BME. Our Department is one of the best known research center worldwide in the field of thermal management and testing. Furthermore, we are conducting high-level research and education activity in the field of micro and nano devices, VLSI electronics, semiconductor sensors and actuators.

History and context of the research

One of the most important application areas of the microsensors and actuators in our days is transport safety, where the most sophisticated systems are used in automobiles and avionics. However, similar devices operate in fire-alarm systems, fingerprint readers, smart phones and numerous other equipments [1], too. Furthermore, several research institutes are working on special biomedical solutions which were unimaginable earlier.

Fig. 1 Smartphone and its sensors

Before these microsystems or MEMS-s are socketed into a daily used sensor system, they have to go through several design cycles. To develop such a device, the detailed operation must be well known which requires exact physical and behavioral models. To determine the material and physical parameters, test structures are developed in the early design phases, which are optimized based on the results of different characterization techniques [2]. But one must anticipate unexpected cross-effects which could influence the operation.

Additionally to these, there is a significant demand for measuring the completed devices and finding the cause of possible malfunctions. For this purpose new kind of measurement solutions should be developed beyond the Design for Testability engineering concepts. When developing the measurement strategies, one has to consider that the measurement itself can affect the operation and the ambient noises can suppress the effective signal.

Aim of the research

During my research I’ve examined two different type of microsystems. One of them operates in the electro-mechanical domains. My primary goals was to investigate the dynamic response of the structure solely by examining the electrical response. This was a difficult task because of the low amplitude of response signal. A further requirement to the measurement procedure was the applicability to packaged devices which can not be investigated with optics.

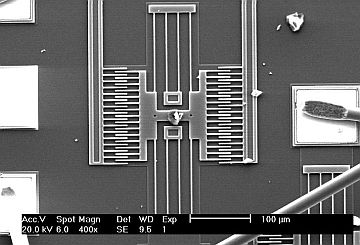

Fig. 2 Electrostatic MEMS

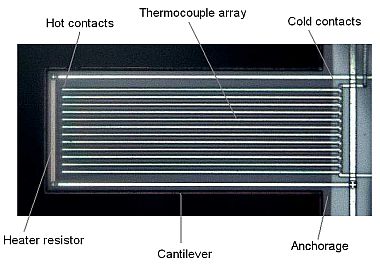

The other microstructure utilizes thermal-electric effects for its operation. My main goal here was developing new measurement procedures to explore both the dynamic and static parameters. Additionally, I also wanted to examine some behaviors and relationships not yet explored. An example for these relationships can be the impact of temperature dependent parameters on the spectrum or the formation of asymmetric heat distribution on symmetric layouts. These effects should be taken into consideration when determining the dynamic and the static parameters, to avoid receiving incorrect results.

Fig. 3 Electro-thermal microsystem

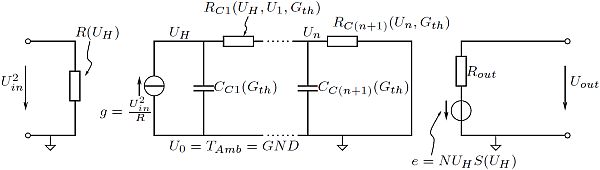

A further aim was to develop an equivalent circuit model for the electro-thermal microsystem which explains all the above effects and can also be used by the MEMS design engineers when developing thermal-electric converters.

Methodology

"Blind" tracing of MEMS

The operation of electrostatic MEMS-s are based on the input voltage which induces mechanical displacement. Several analytical relationships can be formulated between these two parameters which can be verified with special measurement setups. However, to acquire the dynamic properties transient measurements have to be carried out. In these measurements, the input is induced by a step function and the subsequent charge movement is observed at the output. However, due to the low quantity of charge, the measurement is rather sensitive to noise. Depending on the layout of the MEMS, various dynamic analyses can be carried out without optical inspections, for example the determination of the resonance frequency or the pull-in.

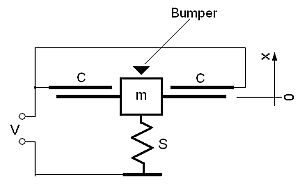

Fig. 4 Schematic of the MEMS with bumper

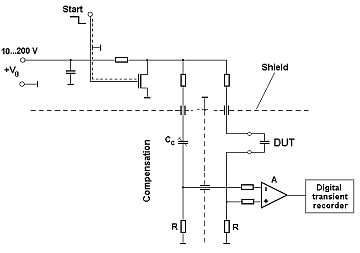

Fig. 5 Setup of the "blind" measurement

Thermal transient testing

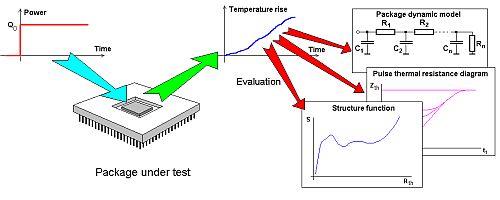

An effective tool of determining the heat resistance and heat capacitance of semiconductor devices is a recent JEDEC standard called thermal transient testing [3]. Additionally to diodes, transistors and their packages, it can also be applied for the measurement of MEMS-s as well. However, due to the usually ms order thermal time constant of microsystems, electric crosstalks can produce significant errors when determining the thermal parameters. This may require additional preprocessing of the output signal before it is evaluated by the standard algorithms.

Fig. 6 Thermal transient testing

New type of measurement setups to compensate for temperature dependence

When measuring various microsystems, additionally to the noise sensitivity unexpected secondary effects can also influence the operation which must be taken into consideration before starting the measurements. When working with µm sized geometries, even low amplitude measurement signals can be the source of errors. An example can be the resistance measurement of a polysilicon heater at the end of a micro console, where the resulting current density can increase the resistor temperature. The inaccuracy produced in this way is highly undesirable in the investigation of electro-thermal microstructures. Although the problem can easily be solved by compensation, the example demonstrates that microdevices operating based on coupled physics have to be investigated with caution.

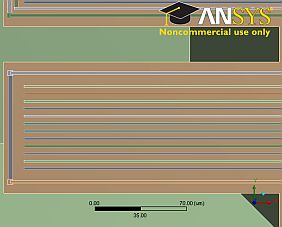

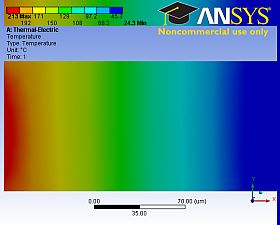

Modeling

The expected behavior of microsystems can be predicted with finite element analysis or circuit simulators [4]. By using cutting edge simulators which are available for the academics, the interactions between different physical regions can be observed (electro-mechanical, electro-thermal). Their solutions can be compared to the measurement results.

Results obtained so far

"Blind” tracing

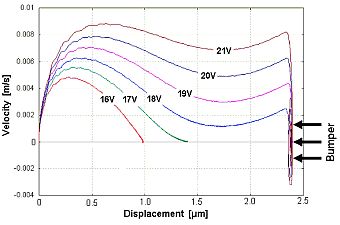

At the beginning of the "blind” measurements, some basic mechanical phenomenon such as resonance frequency and spring damping have been observed. Also, the mechanical pull-in was detected at the structures with bumper. Furthermore, by using the analytical equations, the relationships between displacement or speed against time have been stated solely based on the electrical response. Considering all these, the capacitance vs displacement function could be expressed with current and charges .

Fig. 7 Speed of the movable part of electrostatic MEMS against the displacement trajectories

Crosstalk compensation in thermal transient measurements

The separation of thermal and electrical time constants of the same order of magnitude is essential in obtaining the thermal parameters. As a result of my research, I’ve developed two methods to separate the thermal and electrical transients in the response induced by a step response. Although these methods were only tested on a specific structure they can be generalized to other semiconductor devices.

Asymmetric heat distribution and temperature dependent parameters

Due to the Peltier-effect induced in the polysilicon-aluminum contacts of heating resistors, asymmetric heat distribution have been developed on the symmetric layouts. It can be shown that these asymmetries don’t impact the operation if the layout is properly arranged (serially connected thermocouples). However, it can influence other elements and, through them certain measurement setups (Seebeck-effect has been induced on the contacts of the parallel heating resistors). The temperature dependent parameters also have a significant impact on the operation. Their influence - besides the special measurement setups - can be observed for example in the spectrum where even harmonic components emerges.

Fig. 8 Finite-element analysis: model and temperature distribution

Equivalent circuit

Thanks to the examinations and theoretical analysis, an equivalent circuit of the electro-thermal microsystem has been developed. This circuit describes the thermal domain, contains the coupled physical effects and temperature dependent parameters. Above all the thermal part incorporates the heat conduction of the surrounding gases, which enables future inclusion of gas pressure in the model as well.

Fig 9 Equivalent circuit of the electro-thermal microsystem

Expected impact and further research

The "blind” tracing of mechanical movement of electrostatic MEMS is an effective non-destructive characterization method of packaged devices.

The characterization procedures and special measurement setups used for the investigation of electro-thermal converters can be utilized for other microsystems with similar principle of operation (IR sensor, THz detector, etc.).

The secondary effects revealed and the developed equivalent circuit can also be utilized beyond applied research to develop optimal microsensors for a given specification. Another advantage of the equivalent circuit is giving an opportunity to develop the auxiliary electronics faster and more accurately.

Publications, references, links

List of related own publications

V. Székely, P. G. Szabó

Blind tracing of mechanical movement ind electrostatic MEMS structures.

ANALOG INTEGRATED CIRCUITS AND SIGNAL PROCESSING 71:(1) pp. 11-21. (2012) IF: 0.452

Péter G. Szabó, Vladimír Székely

Investigation of parallel heat flow path in electro-thermal microsystems.

MICROSYSTEM TECHNOLOGIES 17:(4) pp. 533-541. (2011) IF: 1.069

V. Székely, P. G. Szabó

Blind Tracing of Mechanical Movement in Electro-static MEMS Structures.

In: Bernard Courtois, Jean-Michel Karam, Ryutaro Maeda, Pascal Nouet, Peter Schneider, Hsiharng Yang, Collection of Papers Presented at the Symposium on Design, Test, Integration and Packaging of MEMS and MOEMS (DTIP'10). Sevilla, Spain, 2010.05.05-2010.05.07. pp. 39-43. (ISBN: 978-2-35500-011-9)

Péter G. Szabó, Vladimír Székely

Investigation of Parallel Heat-flow Path in Electro-thermal Microsystems.

In: Bernard Courtois, Jean-Michel Karam, Ryutaro Maeda, Pascal Nouet, Peter Schneider, Hsiharng Yang, Collection of Papers Presented at the Symposium on Design, Test, Integration and Packaging of MEMS and MOEMS (DTIP'10). Sevilla, Spain, 2010.05.05-2010.05.07. pp. 215-220. (ISBN: 978-2-35500-011-9)

Péter G. Szabó, Vladimír Székely

Crosstalk Compensation in Thermal Transient Measurements.

In: Proceedings of the 16th International Workshop on THERMal INvestigation of ICs and Systems (THERMINIC'10). Barcelona, Spain, 2010.10.06-2010.10.08. pp. 24-27. Paper 36. (ISBN: 978-2-35500-012-6)

Péter Gábor Szabó, Vladimír Székely

Characterization and modeling of electro-thermal MEMS structures.

MICROSYSTEM TECHNOLOGIES 15:(8) pp. 1293-1301. (2009) IF: 1.025

P. G. Szabó, V. Székely

Characterization and Modeling of an Electro-thermal MEMS Structure.

In: Victor M Bright, Tarik Bourouina, Bernard Courtois, Marc Desmulliez, Jean Michel Karam, Gou-Jen Wang Collection of Papers Presented at the Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS (DTIP'08). Nice, France, 2008.04.09-2008.04.11. pp. 350-354. (ISBN: 978-2-35500-006-5)

B. Németh, P. G. Szabó, V. Székely

Design, Simulation and Measurements of MEMS Test Structures.

In: Proceedings of the 6th Electronic Circuits and Systems Conference (ECS'07). Bratislava, Slovakia, 2007.09.06-2007.09.07. pp. 49-54.

Links.

BME Department of Electron Devices

MEMSnet

https://www.memsnet.org/mems/what_is.html

List of references

- Mohamed Gad-el-Hak "The MEMS Handbook, Second Edition”, CRC Press, 2005

- Martin von Arx, Oliver Paul, Henry Baltes. "Process-Dependent Thin-Film Thermal Conductivities for Thermal CMOS MEMS." 2000.

- Electronic Industries Association, “Transient Dual Interface Test Method for the Measurement of the Thermal Resistance Junction-to-Case of Semiconductor Devices with Heat Flow Through a Single Path”, EIA / JEDEC Standard, JESD51-14, 2010 [www.jedec.org]

- R. Neul. "Modeling and Simulation for MEMS Design, Industrial Requirements." Nanotech 2002 Vol. 1 - Technical Proceedings of the 2002 International Conference on Modeling and Simulation of Microsystems, pages 6–9, 2002.