|

BMe Research Grant |

|

Géza Pattantyús-Ábrahám Doctoral School in Mechanical Engineering

Department of Applied Mechanics

Supervisor: Dr. Zsolt Szabó

Development of dual excenter vibrotactor

Brief introduction of the topic

Contrary to the conventional design, the main concept of dual rotor vibromotor is that two eccentric rotors are driven by two electric motors independently. In this way we can generate vibrations, and with the dual excenter design there is a possibility of adjusting the amplitude and frequency of vibrations independently, so we increase the information transmitted by the vibrations (e.g. vibrating alert of cell phones, medical or rehabilitation applications), or we can generate specified vibrations for various mechanical investigations (e.g. durability tests).

The research is part of the COSMOSYS Hungarian-Singaporean joint project.

Some words about the research place

The research work is conducted at the Department of Applied Mechanics of the Budapest University of Technology and Economics. Although mechanics is a centuries old science, our department participates in the most current research areas as well. Researchers achieved world-class results in the area of machine tool vibrations, time delayed systems, dynamics of robots, wheel-dynamics and continuum-mechanics.

History and context of the research

|

Vibromotor of the iPhone 3g |

Vibromotors are widely used in industrial applications, such as soil- or concrete compacting machines for transporting or selecting pieces, or in fatigue machines for testing materials. However, vibromotors can also be found in smaller applications, e.g. in mobile or medical devices – an area probably better known to the public. The task of these small devices is to transmit information by vibrations via the sensory system of the user’s skin. |

This feedback is also called haptic feedback, and it’s main advantage is that it can take over tasks from the often overloaded sensory (e.g. visual or auditory) channels, or in some cases, it can even substitute them [1].

The most common design of vibromotors are rotating and linear motor designs [2]. There had been researches with vibrating linear motors with the participation of our department, however, in the present study we prefer using rotating vibromotors because of the strait frequency range of linear vibromotors [2].

In the case of rotating vibromotors the limitation is the dependency between amplitude and frequency of the vibration, which can limit the feasibility of the rotating designs.

The aim of the research

|

Common center of mass of rotors in motion |

The aim of the present research is to extend the usability of the rotating vibromotor designs. We invented a dual eccentric design with two independently driven, co-axially placed eccentric rotors. In this way, depending on the angle between the rotors relative to each other at given rotational speed, the amplitude of the vibration can be varied arbitrary between zero and a given value.

|

Some mechanical problems occurred as the mechanical model was built. To assure proper operation of the device these problems have to be investigated.

One of these problems is the “stack” of the electric motors in resonance. In this case “supplying” the increased amplitude vibrations would need so much power that the rotational speed stacks in resonance. The other interesting phenomenon is the synchronization of the rotors. It occurs when the rotational speed of the rotors becomes the equal, even if we would not expect this due to the different supply voltages on the driving motors. The reason is the mechanical coupling between the two rotors.

- An important question: What system parameters and environment do we need to assure to avoid the stack and the synchronization?

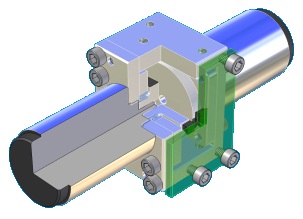

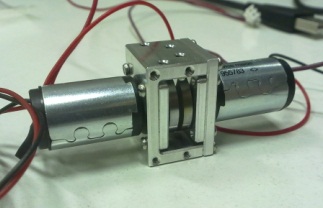

Our main goal is to build an experimental device, which is small enough to prove the concept in small dimensions, but still big enough to make measurements and placing sensors possible.

Methods of the research

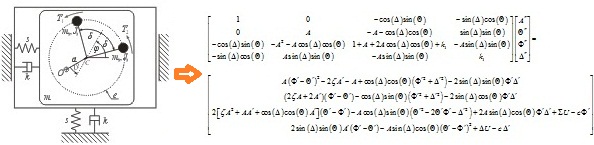

We built a multi-body-system to derive the mechanical and mathematical model of the device. The main parts are the two eccentric rotors, the electric driving motors, the frame, where the motors are mounted and the elastic suspension of the frame that couples our system to the environment. The control system is also a part of the device. It is taken into account as driving torques on the rotors. However, to derive the mathematical model we need to know the control strategy as well. The behavior of the motors is given by their performance. The inputs of the system are the input voltages connected to the motors.

Research steps: mechanical model and the derived equations of motion

|

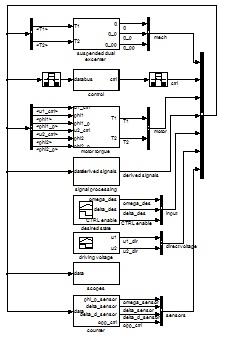

Numerical model for simulation |

A further possible approach is that we build numerical simulation based on the mathematical model. In this way we can approximate the real behavior of the system with high precision. We can take into account inaccuracies in mechanical parameters, discrete behavior of the electronic control system (discrete sampling, digital inputs and outputs, time delay etc.) and the electrical dynamics.

CAD model of the dual excenter |

To build the device, we have to design the parts based on the conceptual design, and we have to manufacture them.

Results

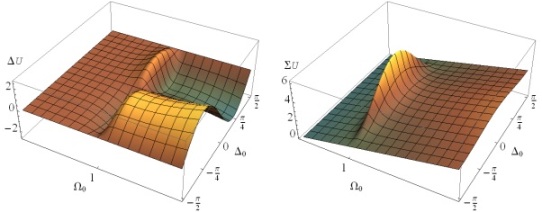

In the current state of the research we have verified the dual excenter concept by numerical simulations. Based on analytical and numerical investigation, we can say that there exist operating points which are stable even without control, so we can set them by simply connecting the specified supply voltages to the motors. However, for fast and accurate functioning we need to control the system. Based on the physical parameters and considering the control strategy we have built a Matlab® Simulink® model.

Difference between the supply voltages of the two motors (left) and the sum of the voltages (right) as the function of the rotational speed of the rotors and phase angle between the rotors in stationary state

Based on the mathematical model we investigated the stationary motions of the system and their stability without control. As a result of these investigations we can draw the modified performance characteristics of the electric motors, and so we have the connection between the supply voltages on the motors and the parameters of the resulting vibration.

|

|

The first prototype of the device is also ready for use, and it can be driven with a control system, implemented in PIC micro-controller. |

Expected impact, further research

The dual rotor vibromotor design offers great possibilities both as an invention and as a scientific topic.

Considering it an invention, our goal is introducing it to the market. As a first step we have already submitted the invention for patent registration, and so we can publish it later on. A next goals is identifying potential industrial partners, and we have to design a device suitable for mass production.

As a scientific topic, the above mentioned mechanical problems (the stack and synchronization) could be very interesting. The publication of these phenomena is in progress, but there are more areas, that could attract the interest of journals with impact factor.

Publications, references, links

Publications related to the research:

Miklós Ákos, Szabó Zsolt, Vibrator with DC motor driven eccentric rotors. Periodica Polytechnika, 2012 (accepted)

Miklós Ákos, Szabó Zsolt, DC motorokkal gerjesztett rendszerek jelleggörbéje rezonanciában és szinkronizációja (in Hungarian), In Proc.: XI. Magyar Mechanikai Konferencia, August 29-31, 2011, Miskolc-Egyetemváros, Hungary, pp. 74. (ISBN: 978-963-661-975-6)

Patent:

Miklós Ákos, Wohlfart Richárd, Tóth András, Stépán Gábor, Jurák Mihály, Eljárás és rezgéskeltő eszköz mechanikai rezgés generálására, Filed 15 May 2012, Filenr: 1215584

Useful links:

[1] Haptic radar