|

BMe Research Grant |

|

Doctoral School of Electrical Engineering

Department of Electronics Technology

Supervisor: Péter Fürjes, PhD

Microtechnology for sciences in biomedicines

Short introduction to the research topic

Silicon and polymer based technology of micro-electromechanical systems (MEMS) is widely used for the fabrication of microscale sensors and actuators e.g. in automotive applications. Versatile advantageous characteristics of technical facilities in the MEMS field open new opportunities to the design and realization of microanalytical systems for biomedics or clinical diagnostics.

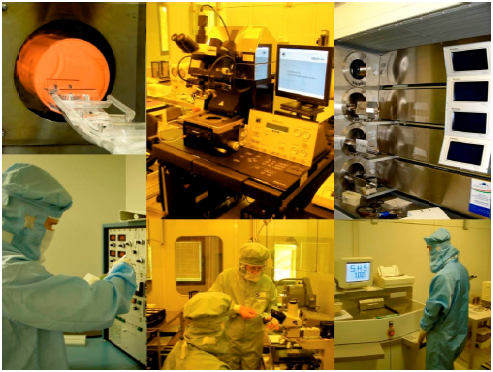

Short introduction of the research laboratory

Micro- and nanotechnology research takes place in the MEMS Lab of the Department of Microtechnology, Institute for Technical Physics and Material Science, RCNS, HAS. A 300 sqrm clean room (class 10 - 10000) with complete Si wafer processing line runs here, which contains full infrastructure for photolithography, thin film depositions and micromachining. The laboratory is in connection with several faculties of BUTE through education (labor practices, supervising research topics of Scientific Students' Associations (TDK) and theses works for undergraduate students as well as leading joint international researches.

Daily activities in the clean lab

History of research

Development of micro- and nanoscale biosensors, biointerfaces as well as microfluidics are emphasized in the activity of MEMS Lab representing state-of-the-art research among the international research community of the field of bioanalytics. R&D activities in the lab generally mean a good opportunity for utilizing the knowledge of undergraduate studies in interdisciplinary field in a creative way. Challenging tasks involve the application of engineering science, and innovative use of microtechnology facilities and processes. On the one hand, basic physical, chemical and biological phenomena are to be investigated at microscale level in order to optimize the functional behavior of microsystems. On the other hand, the investigation of novel sensor principles, and characterization of realized microcomponents are essential in keeping up with the progress in this field.

Goals of research and actual questions

Common feature of all conducted research topics in MEMS Lab is that they focus on actual issues in medical diagnostics, e.g. in situ miniaturized detection of stroke. Taking advantage of unique physical phenomena in the microscale, rapid, efficient and economic performance of bioanalytical tasks can be achieved and evaluated without the assistance of professional personnel. The final goal is to realize chip-scale analytical laboratories, which include sample preparation and transport functions in the form of microfluidic systems, and also contain sensor and transducer structures accompanied by reasonable read-out and evaluation methods. Considering material and production technology, we aim to design inexpensive and disposable cartridges and bioassays, which can be fabricated on a large scale and can be integrated into complex measurement systems.

Methods

Our research lab and the surrounding infrastructure provide us with the opportunity to test new and innovative device concepts from design to fabrication and characterization. Multi-physical simulation codes are available for testing both new sensor principles and fabrication processes. Realization in silicon is supported by a complete MEMS fabrication line, where complex sensors and actuators can be produced with up to sub-micron resolution.

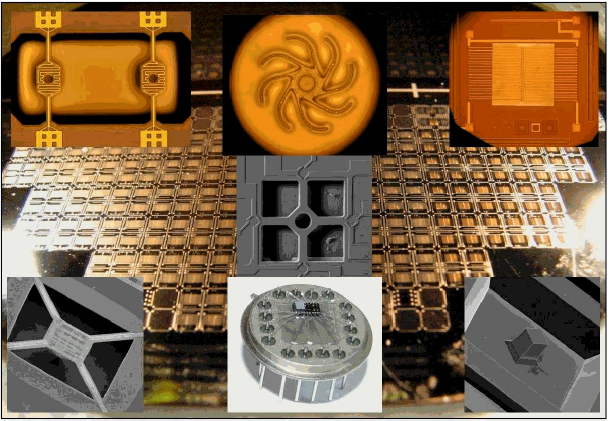

Microscale sensor structures fabricated in MEMS Lab

Fabrication at the micrometer level is supported by the only clean lab environment in Hungary fully equipped with facilities for thin film depositions, photolithography and physical & chemical etching. Moreover, further facilities for functional testing, electrical, mechanical and fluidical measurement platforms and atomic scale structural & analytical microscopy are also available.

Results

During my PhD studies I managed to join several projects detailed below.

a.) b.) c.) d.)

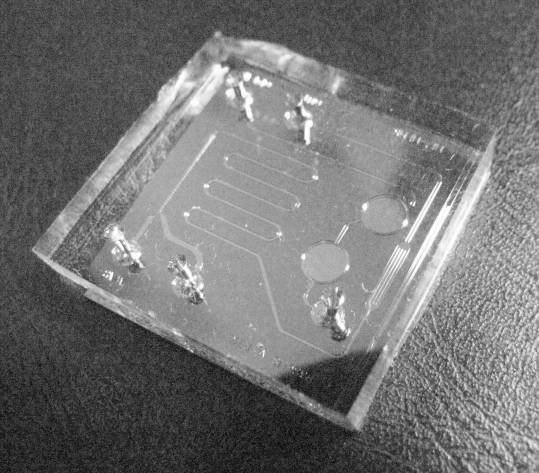

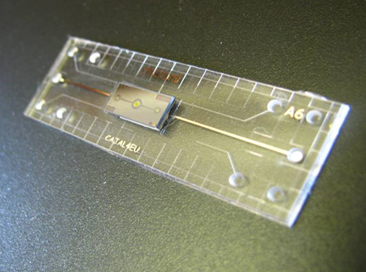

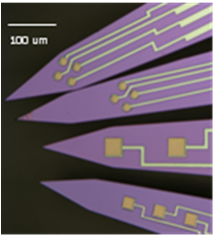

Polymer based microfluidic system (a), silicon microturbine (SEM view) (b.), nanopore sensor chip integrated into microfluidic environment (c.), silicon neural microelectrodes (d.)

I have participated in the development of a Lab-on-a-chip device based on glass-silicon heterostructures, which contains a nanopore sensing structure and a sample preparation microfluidic systems based on Zweifach-Fung separation principle. This project is part of the work of an international consortium (ENIAC CAJAL4EU). The sample preparation system is able to separate blood cells and plasma. By the detection of specific marker proteins in blood plasma, cardiovascular catastrophes can be forecast. Regarding physical (e.g. hydrodynamic) and biochemical (e.g. specific protein immobilization) phenomena, modeling and experimental measurements supported the optimization of the device. Sensing element as solid-state thin film membrane involving nanopore arrays has been fabricated by micro- and nanotechnology (e.g. focused ion beam) methods. The biochemical functionalization of the sensors has been performed by the colleagues in the Department of Inorganic and Analytical Chemistry, BUTE (Group of Robert E. Gyurcsányi).

In the international project of P3SENS I have contributed to the development of polymer based multi-parametric photonic biosensor. We managed to realize a microfluidic environment, which facilitates the biofunctionalized waveguide structure of the photonic chip to be embedded and contains integrated sample preparation functions. This way a novel microanalytical device is proposed.

I have participated in the development of Si-based cortical and deep-brain multielectrodes. I have a submitted patent and several published papers in the field. Our implantable neural electrodes are capable to capture not only the local field potentials of different brain regions but multi and single unit activities, which help us to build a more complex and more precise picture of the nervous system. Our group published the first Si based deep-brain (20-70 mm long) multielectrode with integrated microfluidic channel.

In my diploma work, I presented the versatility of MEMS technology by introducing a combined technique utilizing proton beam writing and porous silicon micromachining, which facilitates the fabrication of complex microstructures e.g. a silicon microturbine. The proposed microdevice won first prize at the International Fair of Inventions and Competition of Graduates in Technical Field, in 2009.

Expected impact and future work

Further improvements in the newly developed biomedical and bioinspired microsystems of MEMS Lab is expected to bring revolutionary results in personalized blood diagnostics as well as in neuroscience at both national and international level. Optimization of developed technologies and metrologies is believed to open doors to the introduction of novel clinical applications. Investigation of microscale physical, chemical and biochemical phenomena in depth can maintain the dynamics of progress in this promising field. In the light of these ideas and considering the interdisciplinary approach of BUTE, new research groups dedicated to biomedical engineering are expected to be established.

List of own publications, references and web links

List of publications:

Z Fekete, P Nagy, G Huszka, F Tolner, A Pongrácz, P Fürjes, Performance characterization of micromachined particle separation system based on Zweifach-Fung effect, SENSORS AND ACTUATORS B-CHEMICAL 162 (2012) 89-94

Z Fekete, A Pongrácz, P Fürjes, G Battistig, Improved process flow for buried channel fabrication in silicon, MICROSYSTEM TECHNOLOGIES (2012) 353-358

Z Fekete, A Pongrácz, G Márton, P Fürjes, On the fabrication parameters of buried microchannels integrated in in-plane silicon microprobes, MATERIALS SCIENCE FORUM (2012), in Press

Z. Fekete, G. Huszka, A. Pongrácz, Gy. Jágerszki, R.E. Gyurcsányi, E. Vrouwe, P. Fürjes, Integrated microfluidic environment for solid-state nanopore sensors, PROCEDIA ENGINEERING (2012), In Press

Z Fekete, E G Holczer, E Tóth, K Iván, P Fürjes, Stochastic mixing in microfluidics integrable in bioanalytical systems, PROCEDIA ENGINEERING 25 (2011) 1229-1232

R E Gyurcsányi, I Makra, Gy Jágerszki, D T Bakk, Z Fekete, G Battistig, I Bársony, P Fürjes

Characterization of solid-state gold nanopores applicable for biochemical sensing, PROCEDIA ENGINEERING 25 (2011) 904-907

Z Fekete, B Sinkovics, I Rajta, G Gál, P Fürjes, Characterization of the end-of-range geometric effects in complex 3D silicon micro-components formed by proton beam writing,

JOURNAL OF MICROMECHANICS AND MICROENGINEERING 20 (2010) 064015

I Rajta, S Z Szilasi, P Fürjes, Z Fekete, Cs Dücső, Si micro-turbine by proton beam writing and porous silicon micromachining, NUCLEAR INSTRUMENTS & METHODS B 267 (2009) 2292-2295

Web links:

- Introduction of

activities in MEMS Lab, interviews for Magyar Rádió in ‘A hely’

(video, voice in Hungarian) - Development of tactile sensing system (article in Hungarian)

- Demonstration of Si microturbine fabricated in MEMS Lab and ATOMKI, HAS (video)

- Demonstration of polymer hydrodynamic focusing chip (video)

- P3SENS (Polymer Photonic multiparametric biochemical SENSor for Point-of-care diagnostics) - official website of the international platform including MEMS Lab as participant (only in English)

- CAJAL4EU (ENIAC project on Nanoelectronics-based biosensor technology platforms) - official website of the international platform including MEMS Lab as participant (only in English)

- Official website of MEMS Laboratory