|

BMe Research

Grant |

|

György Oláh Doctoral School of Chemistry

Department of Organic Chemistry and Technology

Supervisor: Prof. György Marosi

Combined application of chemical imaging and multivariate data analysis (chemometrics) in pharmaceutical and environmental development

Introducing the research area

Chemical imaging is a

fairly novel, continuously growing non-invasive analytical method, which is one

of the most rapidly developing techniques in spectrometry. Its wide range of

applications (both in research and in technological development) include the

analysis of semiconductors [1], medicinal samples [2], paper products [3], food products [4], polymers [5] and pharmaceuticals [6-7]. Since this field poses challenges both in terms of

measurement systems and data evaluation, it seemed and proved an interesting topic for my PhD

studies.

Brief introduction of the research place

The Technology of Pharmaceutical,

Environmental and Safety Materials Research Group, located within the Department of Organic Chemistry and

Technology, conducts various research projects in the development of novel

pharmaceutical technologies [8], upcycling (recycling with

improved value) of polymers [9] and flame retardancy of polymers and structural materials

[10]. Although these areas might seem to be rather

different from one another, they have in fact a lot in common regarding theory

as well as methodology. The research group has access to a wide range of

analytical equipment.

History and context of the research

Chemical imaging is a branch of vibrational spectrometry, since the equipment capable of such analyses comprise a vibrational (infrared, near infrared or Raman) spectrometer and appropriate optics (e.g. microscope). Vibrational spectrometric methods provide information about the molecular structure of the investigated sample. In Raman spectrometry, this information is obtained by illuminating the sample with laser light and collecting the back scattered photons. Such photons with altered wavelength contain the required structural information. Raman spectrometry is highly selective: the spectrum enables unambiguous identification of molecules – just like a fingerprint. Spectra can be used to identify components in the sample, but they carry information about solid state characteristics (e.g. polymorphism) and enable quantitative analysis as well.

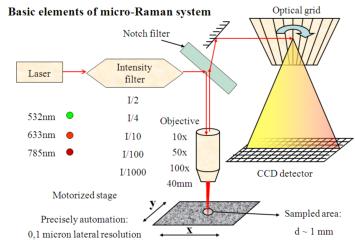

Figure 1. Principles and realization

of chemical imaging. The spatial distribution of various constituents can be

visualized via point-by-point mapping of the surface of interest followed by

adequate mathematical evaluation.

The excitation light can be focused on a very

small area (up to ~0.7 micron in diameter) using a microscope objective with

suitable magnification. Hence, chemical information can be obtained from

micrometer-scale regions of the sample. When chemical imaging is performed, a

user-defined area is scanned by point-by-point spectrum acquisitions. This

set of mapping spectra compose the chemical image, which can then be processed to

reveal the spatial distribution of the components of the sample.

Chemical images contain an enormous amount of

data. Although they can be evaluated via traditional spectrometric approaches,

e.g. plotting the intensity at a selected wavelength against the spatial

coordinates, the huge amount of data can be much better explored using adequate

mathematical methods (called multivariate data analysis or chemometrics). Scientific

achievements in this area have significant importance in medicine, environment-friendly waste

management and recycling and in handling the growing

problem of pharmaceutical counterfeiting. This area is described in detail in two of our review

papers [I,II]. (These reviews are in Hungarian language. Comprehensive

introduction in English can be found in References [6] and [7].)

The research goal, open questions

The primary scope of my research work was to improve the efficiency of chemical imaging methods by implementing adequate mathematical evaluation and identify new potential applications that open up thereby. All analyses in this work were related to technological development projects pursued in our research group, and were thus performed in the frame of industrial or international projects. Multiple questions were to be answered in multiple areas.

(1) Various technologies are available for manufacturing pharmaceuticals. We wanted to determine whether the visualization and statistical analysis of the spatial distribution of components can improve our understanding of the differences between the various manufacturing methods (and the products prepared).

(2) Crystalline impurities in amorphous active

ingredients can greatly deteriorate their dissolution in the stomach and thus

their biological efficiency. Current widely used methods can reliably

detect crystallinity only above approx. 5% crystalline content. We aimed to

greatly increase sensitivity by using Raman mapping. This way, crystal nuclei

can be detected early and stability/shelf life of the products can be estimated

already at the time of manufacture.

(3) A relevant question in both industry and forensics is the characterization of samples containing unknown components (such as illegal drugs, counterfeit pharmaceutical products and industrial products containing unknown impurities due to defects in technology). Unknown components are to be identified, quantified, and their spatial distributions revealed.

(4) An important environmental issue is the

determination of the recyclability of industrial (e.g. automotive, construction

and electrical) waste. Recyclability can depend on major components, trace

contaminants and degraded parts. Currently there is no truly efficient method

for automated, non-invasive analysis of such samples. Hence, we applied Raman

mapping in the automated characterization and quantification of industrial

polymer waste (the constituents of which were not known beforehand) to aid the

recycling process.

Methodology

|

|

All investigations were carried out with a LabRam type

Raman-microscope (Horiba

Jobin Yvon) (with the exception of the reference studies in each

corresponding scientific area). Details and parameters can be found in our

publications [II-XIV]. The sample is illuminated by a (selected) laser source, the beam of

which is focused onto the desired spot with a microscope objective of

selected magnification. Using an appropriate laser source and optional

intensity filters make all of the analyses completely

non-invasive. |

Figure 3: Schematic draft of micro-Raman system |

Back-scattered radiation is collected by the same

objective. Rayleigh photons

(backscattered with unaltered energy/wavelength) are removed with a notch

filter, leaving only Raman photons (with altered energy/wavelength) in the beam.

The light is then directed through a mirror system, a confocal hole and an

entrance slit onto an optical grid which disperses the light before it reaches

the CCD detector.

|

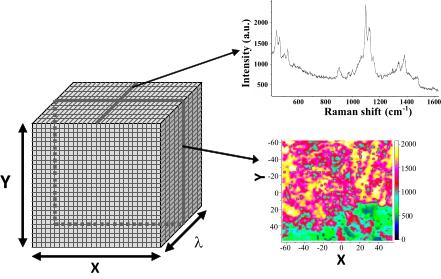

Chemical images have a three-dimensional data structure owing to their

specific acquisition method. Such enormous data sets can be processed with

various mathematical methods (which are reviewed in detail in our paper

[II]). The most common approach is the selection of a suitable vibrational

band, the intensity of which is plotted against the spatial coordinates to

reveal the spatial distribution of components represented by the selected

peak. This approach, however, does not fully utilize the huge amount of data available. Practical issues to be considered are as follows: I. There are numerous substances without a truly selective

vibrational band that can be chosen to distinctively characterize their

distribution (see issues (1) and (2) described earlier.) II. When products with unknown components are characterized,

vibrational bands cannot be assigned to the various constituents (see issue (3)). III. Even after an adequate, thorough spectral

preprocessing, the intensities of vibrational bands may be influenced by noise

and other disturbing factors, so that any characterization based on single bands may

lead to completely misleading results (see issue (4)). |

Figure 4. 3-dimensional data structure of

chemical images. The planes of X,Y coordinates are corresponding to

intensity distribution images at a certain wavelength, while lines in the

Z direction contain the measured spectra at a selected measured point

(pixel). |

Each analysis in our research was carried out by testing multiple algorithms and selecting the best one that provided maximum amount of information at highest accuracy.

Results

(1) Technological characterization of pharmaceutical products

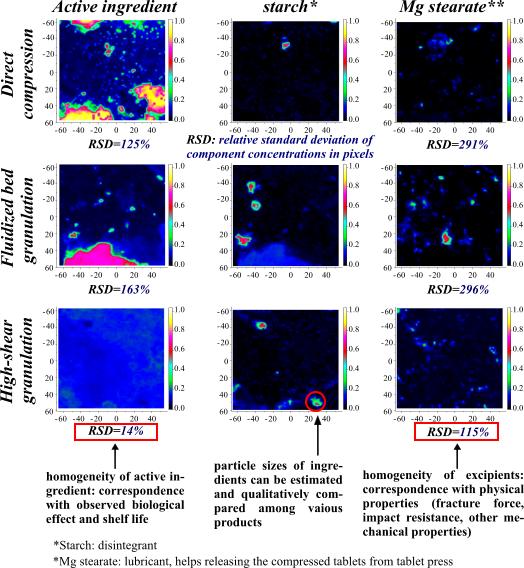

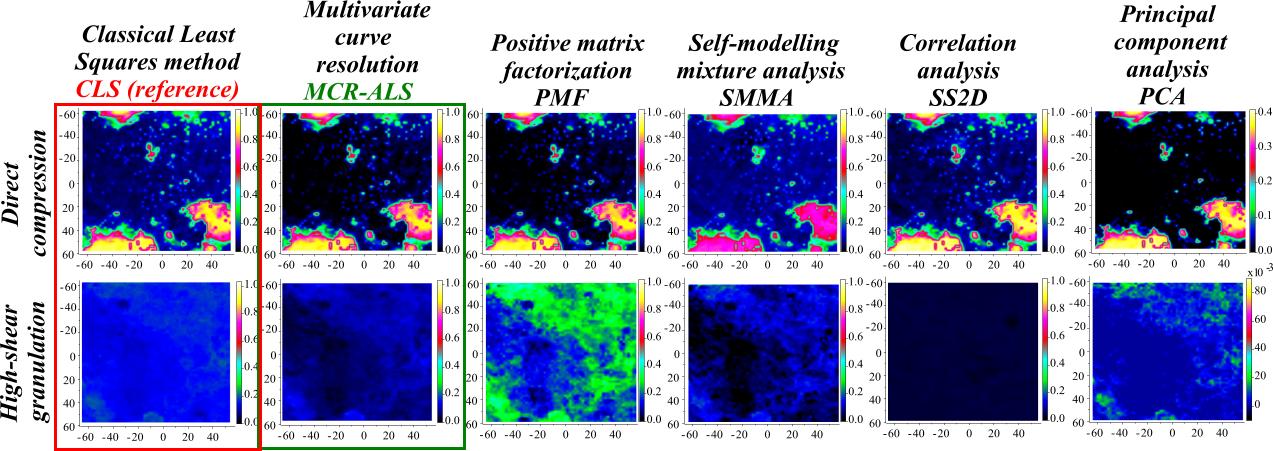

Figure 5. Visualized Raman maps of tablets manufactured with different preparation methods. |

Raman spectra acquired during chemical imaging can be modelled as the

weighted average of the Raman spectra of the pure ingredients (provided

that there are no interactions among them). This enables the estimation of

the concentration of each component for every measured pixel. The

mathematical distribution of the pixel concentrations contain a

significant amount of information about the macroscopic properties of the

products [IV-VII] Model tablets were prepared with seven different manufacturing

technologies, then the differences between these tablets were interpreted

based on the spatial distribution maps of the various components [V]. It was revealed that in possession of certain pieces

of previous information the concentration of all components can be

estimated rather accurately. This approach was used in the case of several products developed in our

research group, where the aim was to finely disperse the active ingredient

in the excipient (polymer) matrix to increase stability [IV, VI, VII]. |

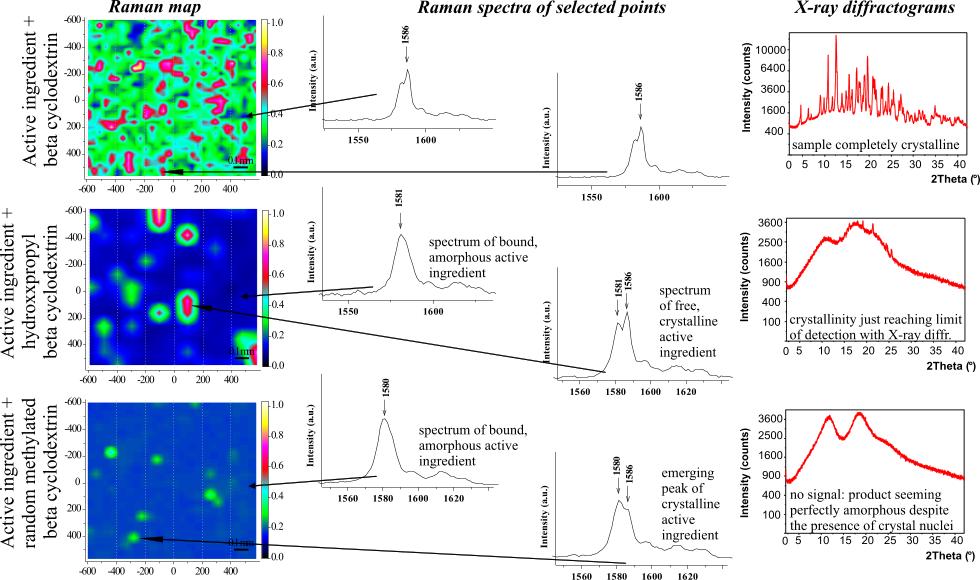

(2) Early detection of crystallization in

amorphous (glass-state) materials

|

Many of the recently developed drugs have extremely poor solubility in the intestinal fluids. One possible solution is manufacturing the drug in amorphous instead of crystalline form, which, however, has to be stabilized. Stabilization can be done by adding excipients that interact with the active ingredients and by using adequate manufacturing technology [III, IV, VI, VII]. Analysis methods of high sensitivity are required for effective fine

tuning of the technological parameters. Using Raman mapping and

multivariate curve resolution algorithms, a new technique with very

high sensitivity was developed for the early detection and quantification

of crystal nuclei [VIII]. |

(3) Characterization of pharmaceutical products with unknown components

Figure 7. Distribution maps of the active

ingredient in two tablets prepared with different manufacturing

technologies, resolved without using any a priori information about

the tablets (as if they were completely unknown). MCR-ALS (green) algorithm resolved the

distribution of all ingredients with almost the same accuracy as if all

components were known and their true reference spectra were used for the

modelling (CLS,

red). The method is non-invasive, hence the tablets can be investigated

further with other techniques. This may play an important role in the

analysis of illegal products. |

Counterfeits, illegal drugs and industrial products containing

impurities are cases where the composition of the samples is unknown.

However, the huge amount of data stored in Raman images enable efficient

estimation of the pure component spectra (even though there are only

mixture spectra in the pixels). Thus, components can be identified and

their concentration and spatial distribution can be estimated [IX-XII]. |

Based on the spatial distribution of the ingredients, important conclusions can be drawn regarding the applied manufacturing technology of the product as well. This makes it possible to determine if two narcotic tablets have been prepared with the same method. This technique allows unambiguous distinction between 'high quality counterfeits' and original products, which currently cannot be reliably carried out with any other method. ('High quality products' can be just as dangerous to patients due to the fact that their manufacturers do not comply with the very strict regulations regarding the manufacturing of pharmaceuticals.)

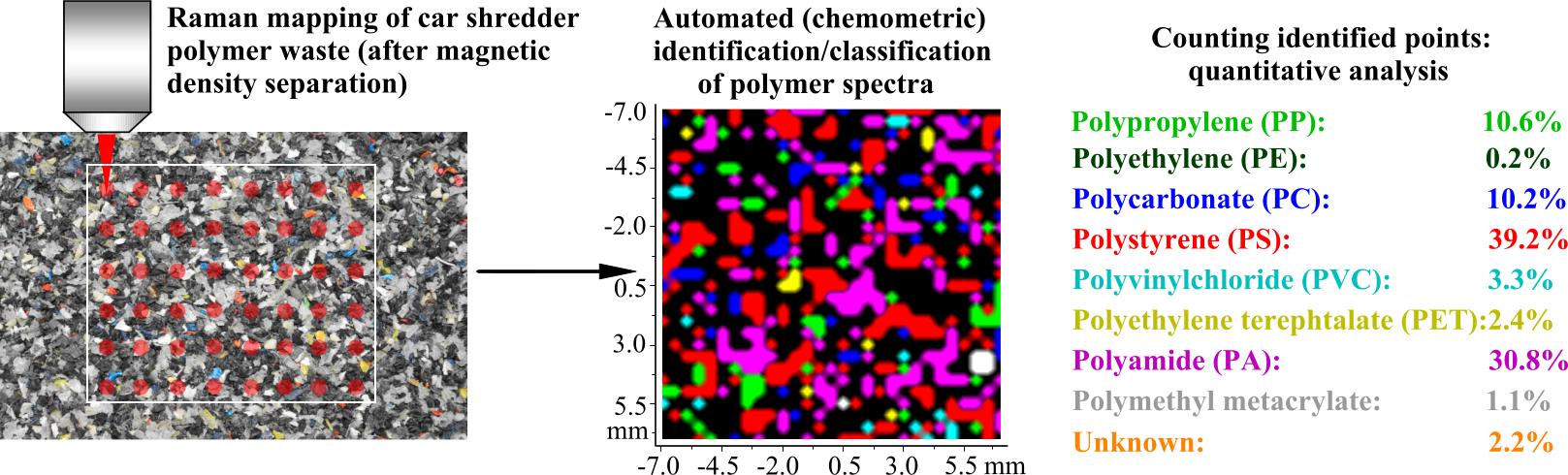

4) Automated characterization of polymer waste

Figure 8. Automated quantitative analysis of polymer waste

Certain multivariate data analysis methods are capable of recognizing (classifying) the Raman spectra. We have recently developed a new method, using multivariate curve resolution algorithms, that do not require knowing the number and identity of the components in the waste sample [XIII]. Despite the extremely low quality of the Raman spectra collected from the waste materials, both major and trace components could be quantified with acceptable error rates [XIII, XIV]. This analytical method was then applied to different types of industrial polymer waste separated into density fractions via magnetic density separation [11]. Based on our Raman mapping results, we could define density intervals so that the separated raw material may be used for high quality recycled products (sample products have been prepared at BUTE Department of Polymer Engineering).

Expected impact and further research

Our group conducts research in the frame

of targeted international R&D projects and in close collaboration with industrial

partners. Our work is also connected to the BUTE Research University

program. We are currently collaborating with three Hungarian and two foreign

pharmaceutical companies that utilize our methods and results. Results shown

here have been published in seven peer-reviewed international and three

Hungarian journals. Furthermore, four of our articles are under review at

present.

Our work will most likely continue in three main

directions. A method is being developed for simultaneous, accurate

quantification (with known

error levels) of all components within a pharmaceutical product. Research will be continued in the area of unknown samples as

well. Furthermore, preliminary studies are being carried out, in collaboration

with the Chemical Research Center in Budapest, for the

application of the highly sensitive SERS

method in Raman mapping.

Publications, references, links

I. B. Vajna, Zs. Nagy, G. Patyi, Zs. Zsolt, I. Antal, Gy. Marosi. Application of chemical imaging in pharmaceutical technology. Acta Pharmaceutica Hungarica, 79, 104–116 (2009).

II. B. Vajna, P. Szepesváry, Gy. Keglevich, Gy. Marosi. Acquisition methods of chemical images and their evaluation with chemometric methods. Hungarian Journal of Chemistry, 116, 77–85 (2010).

III. G. Patyi, A. Bódis, I. Antal, B. Vajna, Zs. Nagy, Gy. Marosi. Thermal and spectroscopic analysis of inclusion complex of spironolactone prepared by evaporation and hot melt methods. Journal of Thermal Analysis and Calorimetry, 102, 349–355 (2010).

IV. Zs. Nagy, M. Sauceau, E. Rodier, B. Vajna, K. Nyúl, Gy. Marosi, J. Fages, Use of Supercritical CO2 aided and Conventional Melt Extrusion for Enhancing the Dissolution Rate of an Active Pharmaceutical Ingredient. Polymers for Advanced Technologies, to be published, DOI: 10.1002/pat.1991 (2011).

V. B. Vajna, I. Farkas, A. Szabó, Zs. Zsigmond, Gy. Marosi. Raman microscopic evaluation of technology dependent structural differences in tablets containing imipramine model drug. Journal of Pharmaceutical and Biomedical Analysis, 51, 30–38 (2010).

VI. Zs. Nagy, A. Balogh, B. Vajna,

A. Farkas, G. Patyi, Gy. Marosi. Comparison of electrospun and extruded,

Soluplus(R) based solid dosage forms of improved dissolution. Journal

of Pharmaceutical Sciences, submitted (2011)

VII. G. Patyi, T. Horváthová, A. Marosi,

B. Vajna, A. Bódis, I. Antal, Zs. Nagy, Gy. Marosi. Complex of

Spironolactone and Hydroxypropyl-β-Cyclodextrin Prepared in Twin-screw Extruder

and Used for Enhancing Dissolution Rate. submitted (2011)

VIII. B. Vajna, I. Farkas, A. Farkas, H. Pataki, Zs. Nagy, J. Madarász, Gy. Marosi. Characterization of drug-cyclodextrin formulations using Raman mapping and multivariate curve resolution. Journal of Pharmaceutical and Biomedical Analysis, in press, DOI: 10.1016/j.jpba.2011.05.005 (2011).

IX. B. Vajna, G. Patyi, Zs. Nagy, A. Farkas, Gy. Marosi. Comparison of chemometric methods in the analysis of pharmaceuticals with hyperspectral Raman imaging. Journal of Raman Spectroscopy, in press, DOI: 10.1002/jrs.2943 (2011).

X. B. Vajna, A. Bódis, Gy. Marosi. Multivariate data analysis in chemical imaging. Journal of the Hungarian Chemical Society, year 65, issue 10, 313–319 (2010).

XI. B. Vajna, A. Farkas, H. Pataki,

Zs. Zsigmond, T. Igricz, Gy. Marosi. Testing the performance of pure spectrum

resolution from Raman hyperspectral images of differently manufactured

pharmaceutical tablets. Analytica Chimica Acta, submitted

(2011).

XII. B. Vajna, H. Pataki, Zs. Nagy,

I. Farkas, Gy. Marosi. Characterization of melt extruded and conventional

Isoptin formulations using Raman chemical imaging and chemometrics. International Journal of

Pharmaceutics, submitted (2011).

XIII. B. Vajna, B. Bodzay, A.

Toldy, I. Farkas, T. Igricz, Gy. Marosi. Analysis of car shredder polymer waste

with Raman mapping and chemometrics. Waste Management, submitted

(2011).

XIV. B. Vajna, K. Palásti, B.

Bodzay, A. Toldy, S. Patachia, R. Buican, C. Catalin, M. Tierean. Complex

analysis of car shredder light fraction. The

Open Waste Management Journal, 3, 47–56 (2010).

[1] S Nakashima. Raman imaging of semiconductor materials: characterization of static and dynamic properties. Journal of Physics: Condensed Matter, 16, S25-S37 (2004).

[2] Y. Zhang, H. Hong, W. Cai. Imaging with Raman spectroscopy. Current Pharmaceutical Biotechnology 11, 654–661 (2010).

[3] P. Tatzer, M. Wolf, T. Panner. Industrial application for in-line material sorting using hyperspectral imaging in the NIR range. Real-Time Imaging 11, 99–107 (2005).

[4] A. Gowen, M. Taghizadeh, C.P. O'Donnell. Identification of mushrooms subjected to freeze damage using hyperspectral imaging. Journal of Food Engineering, 93, 7-12 (2009).

[5] T. Furukawa, H. Sato, Y. Kita, K. Matsukawa, H. Yamaguchi, S. Ochiai, H.W. Siesler, Y. Ozaki. Molecular structure, crystallinity and morphology of polyethylene/polypropylene blends studied by Raman mapping, scanning electron microscopy, wide angle X-ray diffraction, and differential scanning calorimetry. Polymer Journal 38, 1127–1136 (2006).

[6] A.A. Gowen, C.P. O’Donnell, P.J. Cullen,

S.E.J. Bell. Recent applications of Chemical Imaging to pharmaceutical

process monitoring and quality control. European Journal of

Pharmaceutics and Biopharmaceutics 69, 10–22 (2008).

[7] C. Gendrin, Y.

Roggo, C. Collet. Pharmaceutical applications of vibrational chemical imaging

and chemometrics: A review. Journal of Pharmaceutical

and Biomedical Analysis, 48 533–553 (2008).

[8] A. Toldy, N. Tóth, P. Anna, Gy. Keglevich, K.

Kiss, Gy. Marosi. Flame retardancy of epoxy resin with phosphorus-containing

reactive amine and clay minerals. Polymers for Advanced Technologies,

17, 778–781 (2006).

[9] B. Bodzay, B.B. Marosfői, T. Igricz, K. Bocz,

Gy. Marosi. Polymer Degradation Studies Using Laser Pyrolysis-FT-IR

Microanalysis. Journal of Analytical and

Applied Pyrolysis, 85, 313–320 (2009).

[10] Sz. Matkó, I. Répási, A. Szabó, B. Bodzay, P. Anna, Gy. Marosi. Fire retardancy and environmental assessment of rubbery blends of recycled polymers. Express Polymer Letters, 2, 126–132 (2008).

[11] E.J. Bakker, P.C. Rem. Upgrading mixed

polyolefin waste with magnetic density separation. Waste management, 29,

1712–1717 (2009).

Technology of Pharmaceutical, Environmental and Safety Materials Research Group

Department of Organic Chemistry and Technology

equipment of our research group

Chemometrics (multivariate data

analysis)

Attenuated

Total Reflectance (ATR)

Horiba

Jobin Yvon (manufacturer of our LabRam type micro-Raman

spectrometer)