|

BMe Research Grant |

|

BUTE Géza Pattantyús-Ábrahám Doctoral School

Department of Polymer Engineering

Supervisor: Prof. Dr. Vas László Mihály

Development of carbon nanofibrous structures for aeronautical applications

Introducing the research area

Nowadays, carbon fiber reinforced composites

which are related to the most modern group of structural materials (also known

as composites) are applied in many fields where high strength, low weight and

energy-saving are equally required. Typical examples include astronautics, automotive

industry, wind power plants or even sports industry.

Within the framework of

my PhD study nano-sized, high performance carbon reinforcement materials are

being developed, primarily for aeronautical applications. Although these nanofibers are

so small-sized that individual fibers cannot be observed visually, they form

a unique coherent structure (for instance yarn or fabrics) which can be

processed via classical textile or composite industrial processes or even by hand.

Unlike many nano-materials, nanofibrous media do not pose any health-risks

(not carcinogenic, and do not cause silicosis) and may find various

environmental technology related applications (such as drink water or flue gas

filtration).

The establishment and significance of the research topic is well demonstrated by our successful cooperation with the largest European aircraft producer.

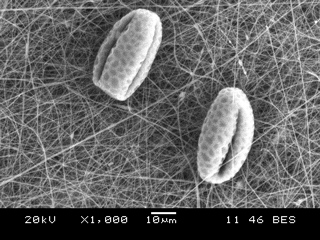

Scanning electron micrograph of pollens of syringa filtered by nanofibers

Brief introduction of the research place

The research work is carried out at the BUTE Department of Polymer Engineering. The Department was the first in Hungary to be eligible for the ISO 9001:2008 certificate; the laboratory and its instruments are accredited by the Hungarian Accreditation Board. Our Department was awarded with “The Greenest Department of the University” title in 2010, as a recognition for its environmentally conscious attitude. Also, eXPRESS Polymer Letters, the journal issued by the Department has gained an impact factor of 1.575 (Thomson Reuters).

History and context of the research

Electrospinning is a process related to nanotechnology. With this method, ultra-fine continuous nanofibrous structures can be produced primarily from polymer materials. The process has a long history, since it was invented in 1902. The topic has only gained high interest in the past two decades, partly due to the lack of modern experimental methods, and partly as a coincidence with the developments in nanotechnology.

The formation and drawing of fibers, the formation of the structure and evolution of the bondings between the fibers cannot be separated in time and in space, i.e. the structure is created in one single step. The process is therefore cost-effective and its implementation on the industrial scale is easy. As a result, nanofibrous materials are widely used not only in industrial but also in household products, like the HEPA filters of vacuum cleaners. The possible applications of electrospun nanofibers include biomedical applications, sensor technology, textile and clothing products, microelectronics, solar cells, building acoustics, and more.

In composite materials, reinforcement is provided by the fibers, but the build up of an adequate adhesion with the matrix material is also required to assure the load bearing property. If an electrospun nanofiber with a diameter of 100 nm = 10-7 m (i.e. an average value when talking about nanofibers) would be stretched between the Earth and the Moon it would have a mass of only 3 g, while its surface would be 120 m2. The unique properties, like the huge specific surface area, the small fiber diameter, the excellent flexural and tensile properties base the application of nanofibers as reinforcement of composites. Having recognized the potential in nanofibers during the last decade, researches aiming at creating carbon nanofibers by various methods has started.

The research goal, open questions

My aim is to develop continuous carbon nanofibers which feature enhanced

tensile properties, easier to process compared to classical carbon fibers and

which, due to their huge

specific surface, can be functionalized and thus may become smart materials. I would like to extend their applications in the composites

industry and establish the possibility of their reproducible, cost-effective,

industrial manufacturing. I would also like to deal with the

structural-geometrical and tensile modeling of nanofibrous

structures.

Among the problems I expect to encounter is e.g. the difficulty

of gaining information about the mechanical properties of single nanofibers. Knowing the properties of single nanofibers is crucial, and currently can only

be determined by difficult and expensive techniques, such as

applying micromanipulators, atomic force microscopy (AFM), scanning

electron microscopy (SEM),

etc. An integral part of my research is the optimization of process methods and

parameters and the development of an electrospinning equipment. The complex problems and question arising during the research will be answered through classical mechanical and

morphological experiments and modelling.

Methodology

Electrospinning – preparation of nanofibers

The nanofibrous structures (yarns and

nonwovens) we develop are made from polyacrylonitrile-based

(PAN) precursor as a base material, which is exactly the same that is used in case of

classical carbon fibers. The precursor fibers are manufactured via electrospinning which uses electrostatic forces to draw the fibers, whereas classical fiber drawing techniques apply mechanical

forces.

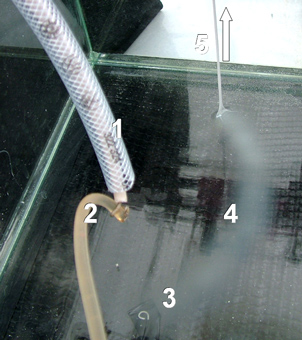

Scheme of electrospinning setup.

1: high voltage power supply, 2: solution feed, 3: polymer

droplet, 4: grounded collector screen

In the most simple case, the electrospinning

setup consists of two electrodes, of which one is the capillary spinneret and the

other one is the collector screen – usually a metal plate. The polymer

solution is fed through the capillary spinneret. As the spinneret electrode is

connected to a high voltage power supply and the collector is grounded, an

electric field develops between them. This electric field can easily interact

with electrically conductive liquids, for instance with polymer solutions. The

surface of continuously supplied droplets form a conical-shape – also known as Taylor-cone – on capillary electrode. From the tip of this cone, one

or more thin jets emerge and carry the electrical charge along. The jets are drawn by electrostatic forces therefore, they become

thinner and thinner as they travel to the collector.

The thinning jet undergoes different bending and

whipping instabilities due to the charges which move to the jet's surface. The

result of the instabilities is that parallel-forming fibers twist and swirl each

other producing a nonvowen, coherent structure. As the solvent is continuously

evaporating from the jet, the fibers generally arrive at the collector surface in solidified form.

Carbonization

The carbonization procedure is basically the same as in the case of classical carbon fibers, but the thermal process parameters are significantly different, because nanofibers are highly sensitive and vulnerable. Carbon fibers can be derived from the precursor material through thermochemical procedures. As a first step, the precursor should be oxidized, which means a thermal treatment at approximately 250-350°C. The base material undergoes the so-called cyclization, which is an exothermic process. The heat energy released can degrade or even burn fibers, therefore, optimization of this step is of crucial importance.

In the next step, the material is heated in

inert atmosphere up to 800-1200°C. The product is a carbon fiber, more than 95% of which is made of carbon atoms. Carbon fibers can be heat treated at

even higher temperatures; the process is called graphitization.

Modeling and mechanical experiments

Learning the mechanical and morphological parameters is absolutely required to attain the adequate material quality. Yarn and nonwoven mat dimensions allow for

performing the traditional tensile tests. However, the properties of

nanofibrous structure differ from those of the fibers composing this structure. Therefore, a fiber bundle cell model developed by my supervisor, László

Mihály Vas and a modeling software developed jointly with Péter Tamás were

adopted for the description of the mechanical properties of single nanofibers and

the damage process of the structure.

Results

Development of electrospinning apparatus

When producing nano-carbon fibers, the nano-structure has to be generated in the first process step. It is done by a self-designed and self-built device. With the aid of a special electrode configuration, known form literature, yarns with potentially infinite length can be produced. The basic steps of process include collection of fibers onto a liquid surface instead of a metal plate collector, and subsequent pulling of these fibers out of the liquid bath using a rotating mandrel. Significant fiber orientation can be achieved as fibers are lifted out of the liquid bath and the structure forms a yarn.

A similar

equipment was built during my research work. With this equipment nanofibrous yarns can be obtained in

continuous mode (with a production speed of 0.01 to 3 m/s). Both fiber diameter

and the fineness of the yarn can be controlled through adjusting setup parameters. A

novel electrode configuration was designed and applied. I showed that the new configuration allows for more homogeneous yarns, which results in higher

tensile values compared to the classical setup.

Self-developed electrospinning device in work.

1: high voltage electrode, 2: PAN solution feed, 3: grounded liquid bath, 4: nanofibrous structure floating on the liquid bath's surface, 5: yarn formation

Modeling

Applying a proper modeling procedure, I showed that the mechanical properties of single nanofibers within nanofibrous mats

and yarns can be evaluated through experiments performed on the nanofibrous structure. The

micromechanical processes which take place during the damage process can also be

revealed. The method proved to be efficient, because my results are in good agreement with

scanning electron microscopic results, as well as with the complicated experiments on single fibers

carried out by other scientists using expensive apparatus. With this method, mechanical properties of single nanofibers can

be determined with a simple experimental technique. The results show that

single nanofibers can have up to three times higher tensile strength compared to the

nanofibrous structure and 50 percent higher than the foil made of the same base

material.

Development of the materials

A unique PAN carbon fiber precursor was

developed, which is both homogeneous and has an average fiber diameter of as low as 350 nm at the same time. The

optimal thermal process of oxidation phase was determined by Differential

Scanning Calorimetry and Thermogravimetric

analysis. We managed to stabilize nanofibrous yarn samples – which is perhaps the most difficult problem of thermal processes – by oxidation. I showed that significant increase of the

tensile properties and fiber orientation can be achieved if

oxidation is carried out applying mechanical stress. Optimization of the

carbonization process is in process and the results will be

published in the near future.

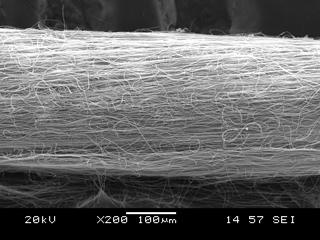

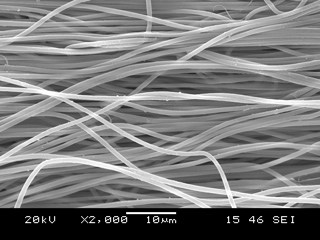

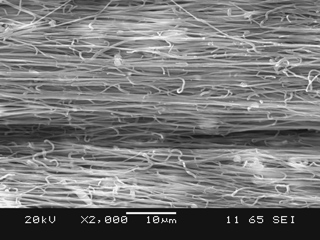

Scanning electron micrographs of PAN carbon fiber precursors

A complex structure was successfully created,

where the nanofibers contain embedded carbon nanotubes of smaller size. Carbon nanotubes are

mixed into the polymer solution and occupy their steady location inside the fibers during

electrospinning. Carbon nanotubes have excellent electrical and thermal

conductivity, are flexible and have great tensile strength and

modulus. I showed that incorporation of carbon nanotubes have a favorable effect on fiber formation and that these materials have enhanced tensile

properties. Carbon nanotubes can play an important role in the carbonization

process as they have a graphitic structure and can increase the molecular

orientation within fibers.

Reeled nanofibrous yarns and scanning electron micrograph of oxidized PAN nanofibers

Expected impact and further research

The modeling method applied in the

development of carbon nanofibers can gain high interest as it can provide accurate results without using expensive apparatus and moreover

it can be generalized and extended to nanofibrous yarns, mats, nonwovens,

fabrics and composites reinforced with these materials. The results can be utilized in the stressing and design of various engineering constructions.

The carbon nanofibers under development

are very flexible, good electrical and thermal conductors, therefore they can be

processed easier during product manufacturing compared to classical

reinforcements. Applying them even in small quantity can lead to significant enhancement in the interlaminar properties of composites. In the future, we

would like to establish the basics of industrial scale production and of the application

of these materials in aeronautics.

Publications, references, links

Publications

1. Kolos Molnár, Eva Košt’áková, László Mészáros. Electrospinning of PVA/carbon Nanotubes Composite Nanofibers: the Effects of Processing Parameters. Materials Science Forum, 589. 221–226 (2008).

2. Kolos Molnár, Zoltán Gombos, László Mihály Vas. Testing and Modeling the Tensile Strength Behavior of Glass Fibers, Fiber Bundles and Fiber Mat. Materials Science Forum, 589. 227–232 (2008).

3. Kolos Molnár, László Mészáros, László Mihály Vas. Processing of Oriented Nanofibers by Electrospinning Method. Gépészet 2008 Konferencia, 2008. máj. 28–29., Budapest.

4. Kolos Molnár, Zoltán Gombos, László Mihály Vas. Testing and Modeling of Glass Fiber Bundles and Glass Fiber Mats. Gépészet 2008 Konferencia, 2008. máj. 28–29., Budapest.

5. Kolos Molnár, László Mészáros, László Mihály Vas. The Effect of Electron Beam Irradiation on PA6/Epoxy Nanofibrous Laminates. Nanofibers for the 3rd Millennium konferencia, 2009. márc. 11-14., Prága (Csehország.

6. László Mészáros, Kolos Molnár, László Mihály Vas. The Effect of the Orientation on the Mechanical Properties of Electrospun Nanofibers. AuTex World Textile Conference, 2009. máj.26-28., Izmir (Törökország).

7. Kolos Molnár, Mathieu Provost, László Mihály Vas. Electrospinning and Characterization of Polyamide Nanofibrous Mats. 3rd Aachen Dresden International Textile Conference, 2009. nov. 26–27., Aachen (Németország).

8. Kolos Molnár, László

Mihály Vas. Electrostatic Spinning and Possible Applications in Composite Industry (in Hungarian).

Erősített Műanyagok 2010 Nemzetközi Balaton Konferencia, 2010. máj. 18-20.,

Keszthely. (In Hungarian)

9. Kolos Molnár, Eva Košt’áková, László Mihály Vas. Preparation of Composites Reinforced with ‘In Situ’ Electrospun Fibres. ECCM14 - European Conference on Composite Materials, 2010. jún. 7-10., Budapest.

10. Zsombor Kristóf Nagy, Katalin Nyúl, István Wagner, Kolos Molnár, György Marosi. Orally Dissolving Web (ODW) of Water Solving Polymer for Ultrafast Drug Release. Express Polymer Letters 4:12, 763–772 (2010).

11. Kolos Molnar, Laszlo Mihaly Vas, Tibor Czigany. Testing and modeling the tensile process of electrospun nanofibrous structures. Proceeding of the 2nd International Conference on Nanomechanics & Nanocomposites, 2010.okt.10-13. Peking: pp. 87–90 Peking (Kína).

12. Kolos Molnár.

Composite Industrial Application of Electrospun Nanofibers (in Hungarian). Magyar

Textiltechnika 2011:1, 2–7 (2011). (In Hungarian)

13. Kolos Molnar, Laszlo Mihaly Vas, Tibor Czigany. Determination of tensile strength of electrospun single nanofibers through modeling tensile behavior of the nanofibrous mat (to appear) Composites part B: Engineering doi:10.1016/j.compositesb.2011.04.024 (2011).

References

[1] He J.-H., Liu Y., Mo L.-F., Wan Y.-Q., Xu L. Electrospun nanofibres and their applications. iSmithers, Shawbury, United Kingdom (2008).

[2] Andrady A. L. Science and technology of polymer nanofibers. John Wiley & Sons, Inc., New Jersey (2008).

[3] Zhao J., Jia C., Duan H., Li H., Xie E. Structural

properties and photoluminescence of TiO2 nanofibers were fabricated by

electrospinning. Journal of Alloys and Compounds, 461, 447–450 (2007).

[4] Tripatanasuwan S., Zhong Z., Reneker D.H. Effect of evaporation and solidification of the charged jet in electrospinning of Poly(ethyleneoxide) aqueous solution. Polymer, 48, 5742–5746 (2007).

[5] Ishii D., Lee W. K., Kasuya K. I., Iwata T. Fine structure and enzymatic degradation of poly[(R)-3-hydroxybutyrate] and stereocomplexed poly(lactide) nanofibers. Journal of Biotechnology, 132, 318–324 (2007).

[6] Rutledge G. C., Fridrikh S.V. Formation of fibers by electrospinning. Advanced Drug Delivery Reviews, 59, 1384–1391 (2007).

[7] Burger C., Hsiao B.S., Chu B. Nanofibrous materials and their applications. Annual Review of Materials Research, 36, 333–368 (2006).

[8] Smit E., Bűttner U., Sanderson R.D. Continuous yarns from electrospun fibers. Polymer, 46, 2419–2423 (2005).

[9] Gu S.Y., Wu Q., Ren J. Preparation and surface structures of carbon nanofibers produced from electrospun PAN precursors. New Carbon Materials, 23, 171–176 (2008).

[10] Moon S., Farris R.J. Strong electrospun nanometer-diameter polyacrylonitrile carbon fiber yarns. Carbon, 47, 2829–2839 (2008).

[11] Zussman E., Chen X., Ding W., Calabri L., Dikin D.A., Quintana J.P., Ruoff R.S. Mechanical and structural characterization of electrospun PAN-derived carbon nanofibers. Carbon, 43, 2175–2185 (2005).